Additive Manufacturing software landscape

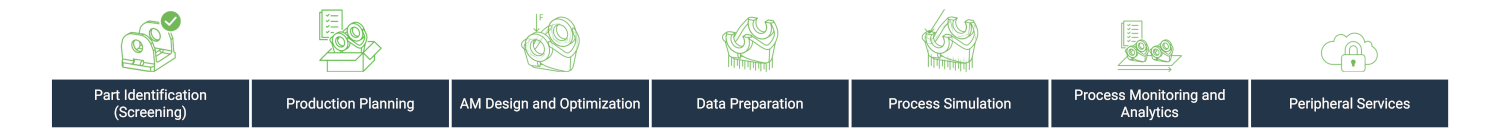

Additive Manufacturing software solutions are a key to enable engineers to fully leverage the potential of AM. Software solutions today cover the full process chain of AM and can lead to a digital thread along the manufacturing and engineering process. In this Software landscape, AMPOWER breaks down the Additive Manufacturing software solutions along the process chain starting with part identification and application screening. The next process step is production planning, often associated with so called Manufacturing Execution System (MES) Software. While many companies adapt their existing MES solutions to integrate Additive Manufacturing, there are also proprietary solutions available that completely focus on Additive Manufacturing.

The first part of the actual manufacturing process is covered by Additive Manufacturing software solutions dedicated to design and optimization of part geometries. Those often involve solutions that focus on unique capabilities that AM enables such as lattice structures and internal structures. Often optimization algorithms are combined with those solutions to design for example topology optimized parts for fluidic or load bearing applications.

Data preparation has been an essential Additive Manufacturing software field. Solutions are typically starting by taking 3d geometries and positioning and nesting them in the build chamber of the 3D Printer. Optimization algorithms identify the ideal orientation to increase nesting density, avoid supports and optimize powder recovery. Also, parameter optimization is often part of those solutions. The final step of those solutions often is a build file, which contain sliced data and parameter for the actual build job. Process simulation tools are often already integrated in certain data preparation tools. Especially in complex technologies such as Laser Powder Bed Fusion, simulation plays an integral role in optimizing orientation, support geometries and print parameters.

In process monitoring and analysis has proven to be a highly complex field in the Additive Manufacturing software landscape. While some solutions cover quite simple operations to keep track of machine parameters and systematically monitor data, others try to measure the print quality within each layer by analyzing camera or other sensory data. Especially for production environments, where similar parts are printed in higher volumes, those solutions have become viable for some operators to monitor quality during build jobs.

Over the years, many Additive Manufacturing software vendors have developed further peripheral solutions in various fields, to support AM users. Those can be tools for quote and order management, LCA solutions or IP protection for 3D printing files.

The AMPOWER Additive Manufacturing software landscape lists nonproprietary software vendors along the described process chain. This means, that only solutions, that can be used for third party printers and are no restricted to certain models, are listed in the map. This allows AM users, to identify potential partners for specific software topics. The landscape is subject to continuous updates and improvements. Any feedback is welcomed. Our vision is to support AM users to fully utilize the technology and identify suitable Additive Manufacturing software solutions for their needs.

Download the Additive Manufacturing software landscape here

We provide the technology overview as a free download in PDF format. You are welcome to include the overview in your documents, stating the source.