https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability

https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing SustainabilityPublications and Whitepapers

AMPOWER Insights

https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability

https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

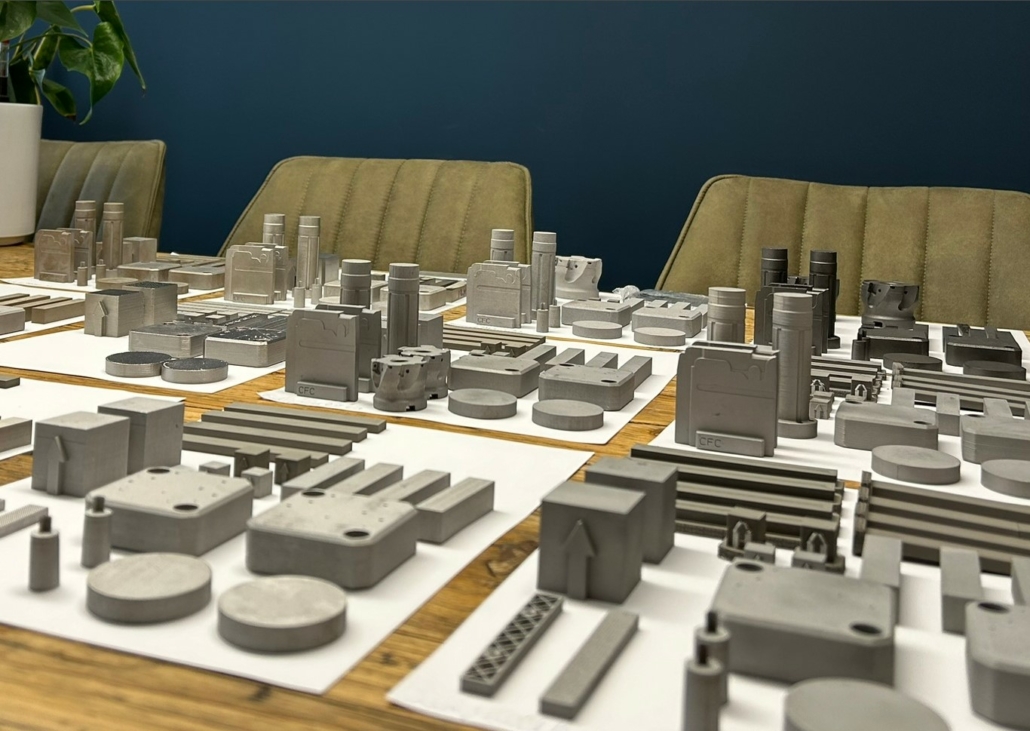

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation

https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

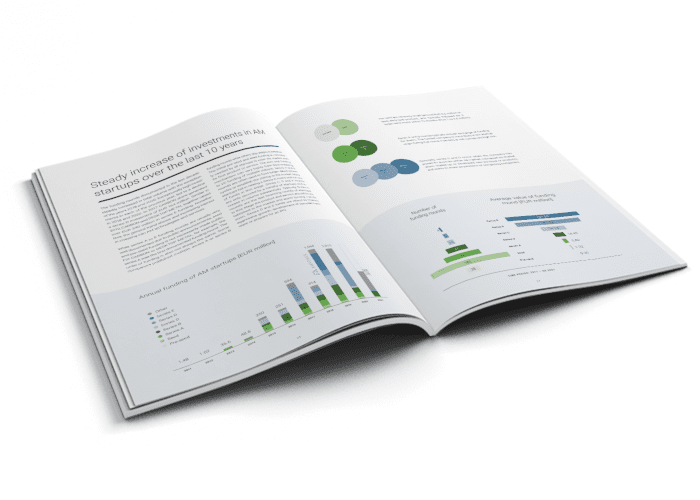

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

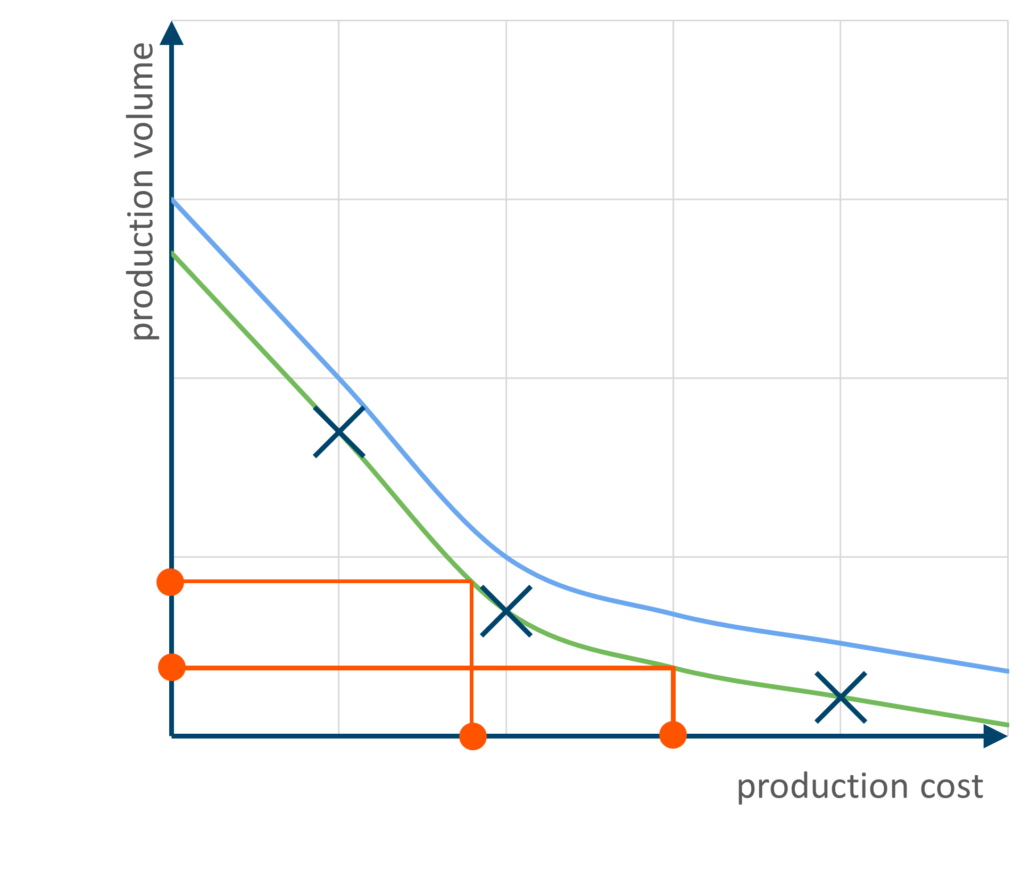

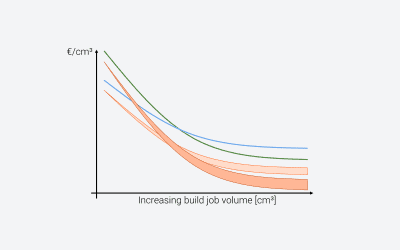

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing

https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

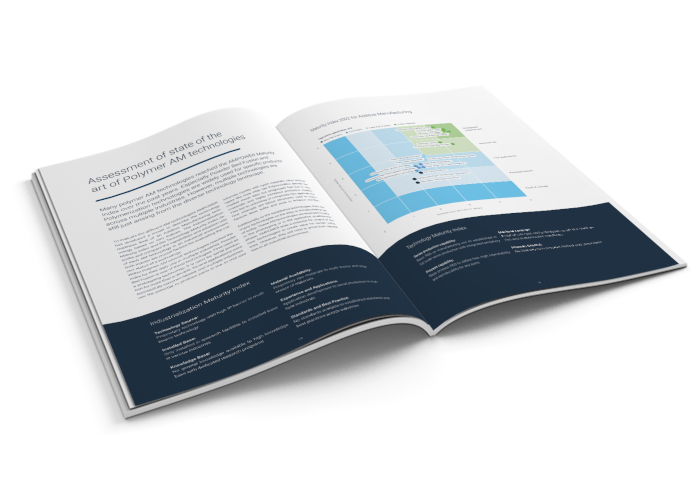

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies

https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing

https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

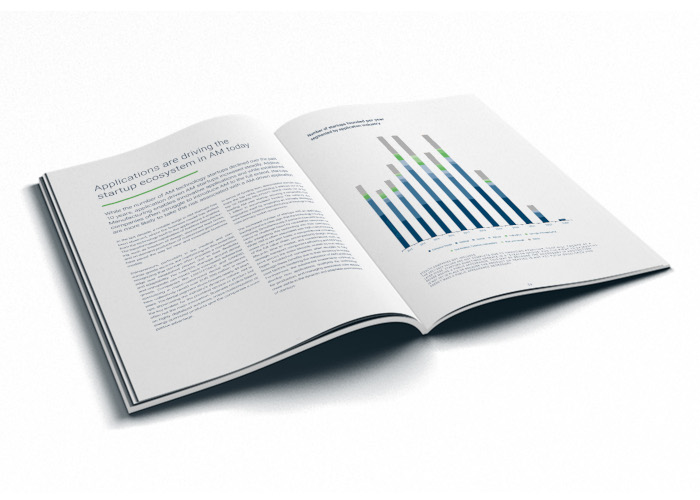

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups

https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

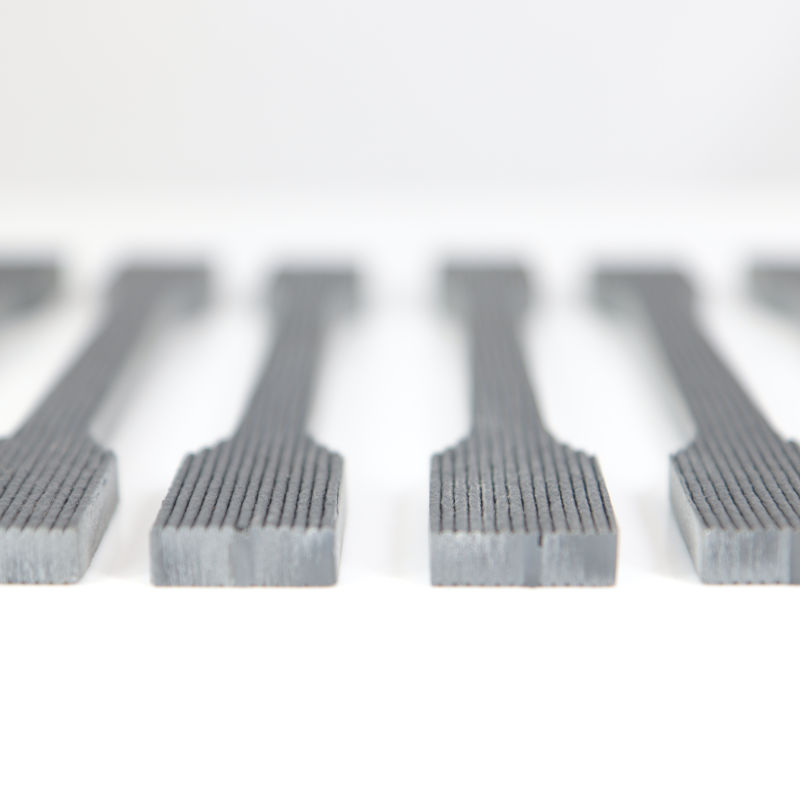

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

Material Performance Optimization of AM Titanium

InsightsVolume 7 Part 1

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers

https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting

https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive Components

https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive Components https://ampower.eu/wp-content/uploads/2017/10/was-ist-additive-fertigung-kosten.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

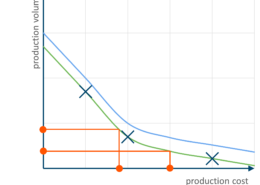

matzesl2017-10-06 22:49:492023-02-15 08:58:23Evaluation of Cost in Additive Manufacturing - A Guide to Make or Buy

https://ampower.eu/wp-content/uploads/2017/10/was-ist-additive-fertigung-kosten.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2017-10-06 22:49:492023-02-15 08:58:23Evaluation of Cost in Additive Manufacturing - A Guide to Make or Buy https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability

https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation

https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing

https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies

https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing

https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups

https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

Material Performance Optimization of AM Titanium

InsightsVolume 7 Part 1

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers

https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting

https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive Components

https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive Components https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability

https://ampower.eu/wp-content/uploads/2025/04/Polymer-Additive-manufacturing-sustainability-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2025-04-01 11:56:022025-04-01 12:21:54Polymer Additive Manufacturing Sustainability https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation

https://ampower.eu/wp-content/uploads/2024/05/metal-binder-jetting-implementation.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-05-02 10:50:472024-05-02 13:06:37Metal Binder Jetting Implementation https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2024/02/venture-capital-in-additive-manufacturing.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-02-05 16:23:312024-02-26 14:36:28Venture Capital in Additive Manufacturing https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing

https://ampower.eu/wp-content/uploads/2023/09/additive-manufacturing-cost-and-market-pricing-1.jpg

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-09-28 15:26:512024-03-19 12:55:34Additive Manufacturing Part Cost and Pricing https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies

https://ampower.eu/wp-content/uploads/2022/11/polymer-am-technology-study.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-11-10 11:39:532023-05-01 12:28:42New polymer Additive Manufacturing technologies https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing

https://ampower.eu/wp-content/uploads/2022/09/additive-manufacturing-metal-sustainability.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2022-09-29 09:56:382024-03-18 21:41:19Sustainability of Metal Additive Manufacturing https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups

https://ampower.eu/wp-content/uploads/2021/11/startups-additive-manufacturing.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2021-11-02 20:54:362022-09-30 21:00:00Additive Manufacturing Startups https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

https://ampower.eu/wp-content/uploads/2021/05/design-for-binder-jetting.png

500

700

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-05-07 16:28:272021-11-10 13:22:17Design guideline for sinter-based Additive Manufacturing

Material Performance Optimization of AM Titanium

InsightsVolume 7 Part 1

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies

https://ampower.eu/wp-content/uploads/2020/02/New-Technologies-Additive-Manufacturing.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2020-02-28 14:49:322022-09-30 21:01:46New and Upcoming Metal AM Technologies https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers

https://ampower.eu/wp-content/uploads/2018/11/Mockup-strategy-380.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-03-08 15:10:562022-09-30 21:02:22Additive Manufacturing Business Strategy for Users and Suppliers https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing

https://ampower.eu/wp-content/uploads/2018/11/Qualität-in-der-Additiven-Fertigung-open-sm.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-11-02 08:35:322022-09-30 21:02:49Quality Management and Best Practices in Additive Manufacturing https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting

https://ampower.eu/wp-content/uploads/2018/10/Sinter-Insight.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-10-10 17:25:052022-09-30 21:03:17Evaluation of Sinter-based Technologies such as Binder Jetting https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive Components

https://ampower.eu/wp-content/uploads/2018/02/was-ist-additive-fertigung-automobilbau.png

270

380

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2018-02-21 20:29:052021-11-30 10:00:45Successful Additive Manufacturing of Automotive ComponentsKnowledge

Market and Technology Studies

AMPOWER

AMPOWERTool steel

StudiesThe study provides a state-of-the-art overview of tool steel processing using AM technologies. Overall, 8 different tool steels and 18 process and material combinations are studied.

AMPOWER

https://ampower.eu/wp-content/uploads/2022/09/add-market-03-preview.png

1637

1936

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2022-09-29 15:38:142023-12-04 14:26:06Addressable Market Metal AM

AMPOWER

https://ampower.eu/wp-content/uploads/2022/09/add-market-03-preview.png

1637

1936

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2022-09-29 15:38:142023-12-04 14:26:06Addressable Market Metal AM AMPOWER

https://ampower.eu/wp-content/uploads/2021/10/copper-am-overview-samples.jpg

589

782

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

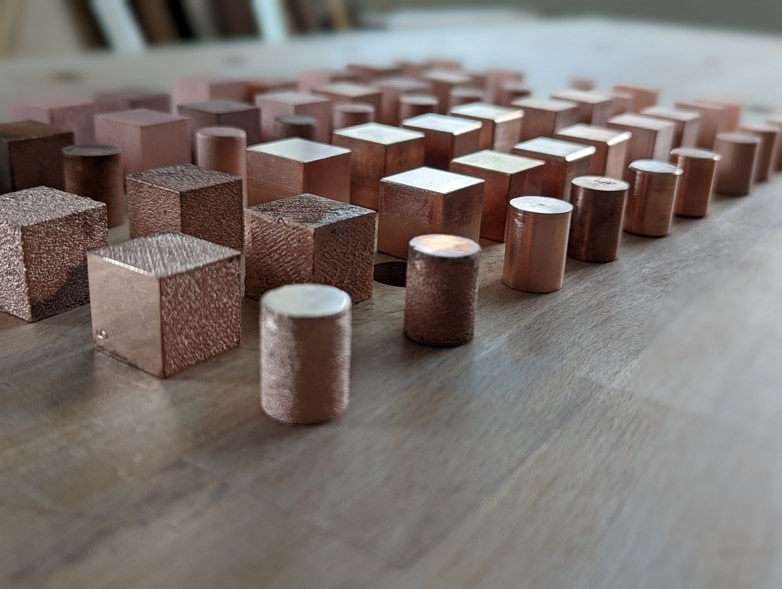

Maximilian Munsch2021-10-11 15:23:252023-01-20 09:20:11Copper Additive Manufacturing

AMPOWER

https://ampower.eu/wp-content/uploads/2021/10/copper-am-overview-samples.jpg

589

782

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2021-10-11 15:23:252023-01-20 09:20:11Copper Additive Manufacturing AMPOWER

https://ampower.eu/wp-content/uploads/2020/08/img_9645.jpg

800

800

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2020-08-11 08:44:152021-11-09 15:35:34Composite Additive Manufacturing

AMPOWER

https://ampower.eu/wp-content/uploads/2020/08/img_9645.jpg

800

800

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2020-08-11 08:44:152021-11-09 15:35:34Composite Additive Manufacturing AMPOWER

AMPOWERTool steel

StudiesThe study provides a state-of-the-art overview of tool steel processing using AM technologies. Overall, 8 different tool steels and 18 process and material combinations are studied.

AMPOWER

AMPOWERAddressable Market Metal AM

StudiesIn this study, AMPOWER presents an objective and independent analysis beyond the current AMPOWER Report data. By analyzing nine material groups in seven industries, AMPOWER shows how decreasing production costs can increase the potential metal AM market.

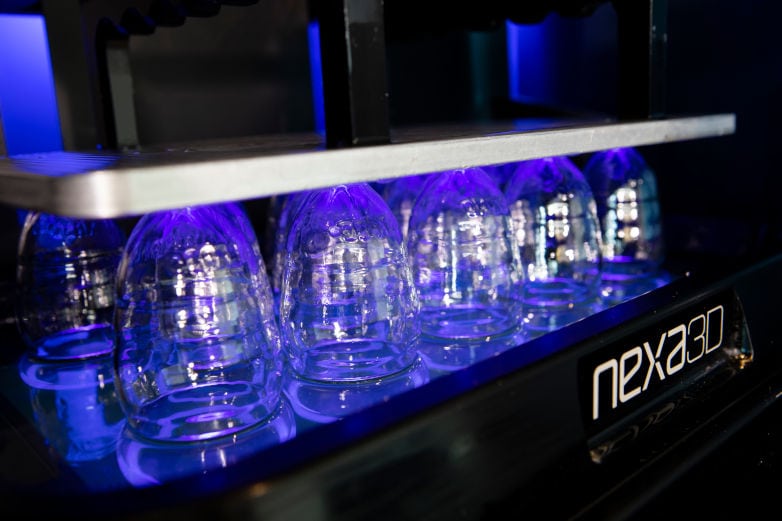

Advancements in Photopolymer AM

StudiesAMPOWER challenges the maturity of AM Photopolymer technologies and benchmarks several systems in terms of material properties, productivity, economical and sustainability aspects.

AMPOWER

AMPOWERCopper Additive Manufacturing

StudiesOut of the 20 different metal AM technologies AMPOWER categorizes today, vendors of half a dozen technologies have introduced processing of copper and another half a dozen researches the use. AMPOWER assessed the maturity, productivity and cost structure.

AMPOWER

AMPOWERComposite Additive Manufacturing

StudiesProcessing of composite materials is a fast growing field within the field of Additive Manufacturing. Today, more than 19 companies develop technology to offer solutions that enable 3D printed components made from composite materials and continuous fibers.

AMPOWER

AMPOWERCost of Additive Manufacturing

StudiesAMPOWER conducted a market study on actual costs in Additive Manufacturing to provide an overview on the status quo and to answer several key questions. Firstly, how much does AM cost internally and externally today, how will these costs develop in the future?

AMPOWER

AMPOWERDirect Energy Deposition

StudiesAMPOWER performed a detailed study on surface finishing processes of metal AM parts. The study included research on surface finishing processes, their advantages, use cases and details on the cost structure. In total, 10 different processes that allow (semi-)automatic surface finishing were tested empirically using LB-PBF specimens and 4 different alloys: AlSi10Mg, Ti-6Al-4V, 316L and nickel-based 718.

AMPOWER

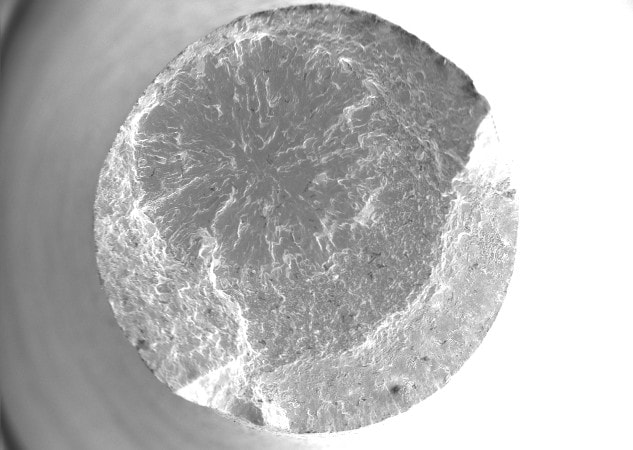

AMPOWERHot Isostatic Pressing Of Titanium AM Parts

StudiesTo advance the knowledge on HIP treatments for AM parts, while enhancing AM specific material properties, AMPOWER investigates and optimizes HIP cycles for LB-, EB-PBF and BJT in this study.

AMPOWER

AMPOWERSurface Finish

StudiesAMPOWER performed a detailed study on surface finishing processes of metal AM parts. The study included research on surface finishing processes, their advantages, use cases and details on the cost structure. In total, 10 different processes that allow (semi-)automatic surface finishing were tested empirically using LB-PBF specimens and 4 different alloys: AlSi10Mg, Ti-6Al-4V, 316L and nickel-based 718.

AMPOWER

AMPOWERSinter-based technologies

StudiesIn this study, AMPOWER presents an objective and independent view on the current capabilities of sinter-based AM technologies compared with LB-PBF and metal injection molding (MIM). By analyzing over 50 specimens from 9 different system suppliers, AMPOWER is revealing the characteristics of the different technologies.

Infographics

Useful Infographics, Tools and Databases

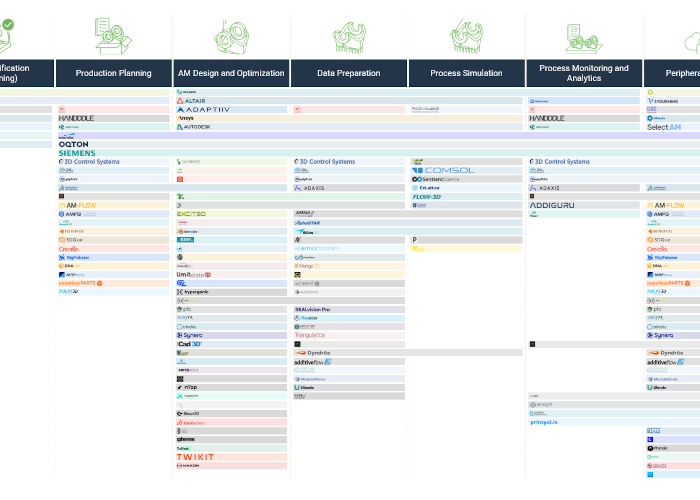

Technology Overview Additive Manufacturing Software

InfographicsAdditive Manufacturing software solutions enable user to leverage the full potential of AM. This map provides an overview of all nonproprietary solutions.

Technology Overview Ceramic Additive Manufacturing

InfographicsCeramic, sand and concrete 3D printing is more diverse today than ever. AMPOWER provides an overview and classification of the important processes.

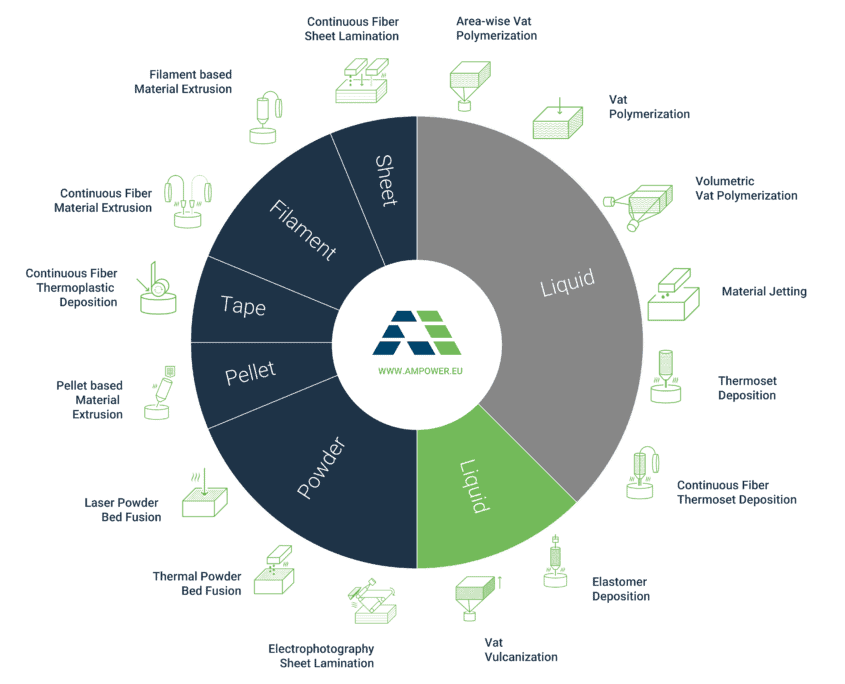

Polymer Additive Manufacturing Technology Overview

InfographicsThe first Additive Manufacturing process was based on Polymer 3D printing. Today, we know over 16 different processes.

AMPOWER

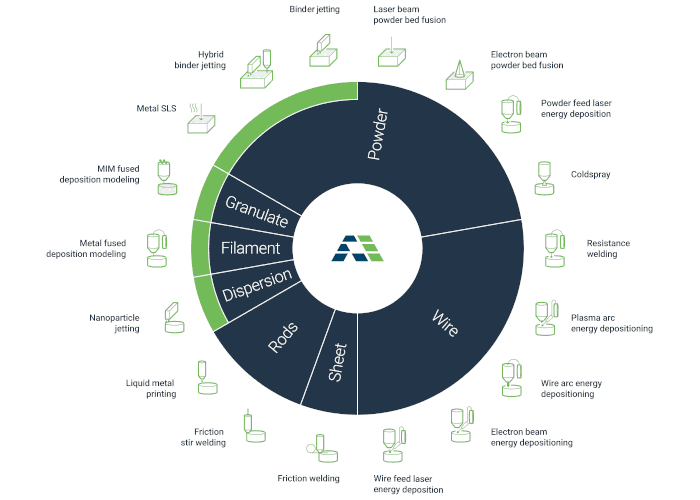

AMPOWERMetal Additive Manufacturing Technology Overview

InfographicsMetal 3D printing is more diverse today than ever. AMPOWER provides an overview and classification of the important processes.

https://ampower.eu/wp-content/uploads/2024/03/titelbild-software.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-03-18 20:44:192024-03-18 20:46:04Technology Overview Additive Manufacturing Software

https://ampower.eu/wp-content/uploads/2024/03/titelbild-software.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2024-03-18 20:44:192024-03-18 20:46:04Technology Overview Additive Manufacturing Software https://ampower.eu/wp-content/uploads/2023/06/ceramic-additive-manufacturing-technology-map-ampower-vorschau-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-06-15 11:44:332024-03-13 17:58:21Technology Overview Ceramic Additive Manufacturing

https://ampower.eu/wp-content/uploads/2023/06/ceramic-additive-manufacturing-technology-map-ampower-vorschau-1.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2023-06-15 11:44:332024-03-13 17:58:21Technology Overview Ceramic Additive Manufacturing https://ampower.eu/wp-content/uploads/2020/08/polymer-additive-manufacturing-technology-overview.png

4176

5535

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2020-08-11 12:12:502025-02-18 12:40:06Polymer Additive Manufacturing Technology Overview

https://ampower.eu/wp-content/uploads/2020/08/polymer-additive-manufacturing-technology-overview.png

4176

5535

Maximilian Munsch

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

Maximilian Munsch2020-08-11 12:12:502025-02-18 12:40:06Polymer Additive Manufacturing Technology Overview AMPOWER

https://ampower.eu/wp-content/uploads/2019/05/matall-additive-fertigung.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-10-15 07:13:302024-07-24 09:56:23Metal Additive Manufacturing Technology Overview

AMPOWER

https://ampower.eu/wp-content/uploads/2019/05/matall-additive-fertigung.png

500

700

matzesl

https://ampower.eu/wp-content/uploads/2020/07/Logo-1.png

matzesl2019-10-15 07:13:302024-07-24 09:56:23Metal Additive Manufacturing Technology OverviewAMPOWER Report

Download the AMPOWER Report Management Summary

Find out more about the new AM market report reference:

Be successful with AM: Read AMPOWER Insights