Study description

Processing of composite materials is a fast growing field within the field of Additive Manufacturing. Today, more than 19 companies develop technology to offer solutions that enable 3D printed components made from composite materials and continuous fibers.

AMPOWER conducted the technology study to evaluate the status quo of processing composite materials with Additive Manufacturing. Following key questions were answered. What is the current status of the technology to produce composite materials with AM? What are the costs? What are the resulting material properties?

The analysis includes an evaluation of the specific process chain including the digital processing, the cost and productivity, materials properties, among others.

AMPOWER conducted the study from mid 2020 to mid 2021.

Study results

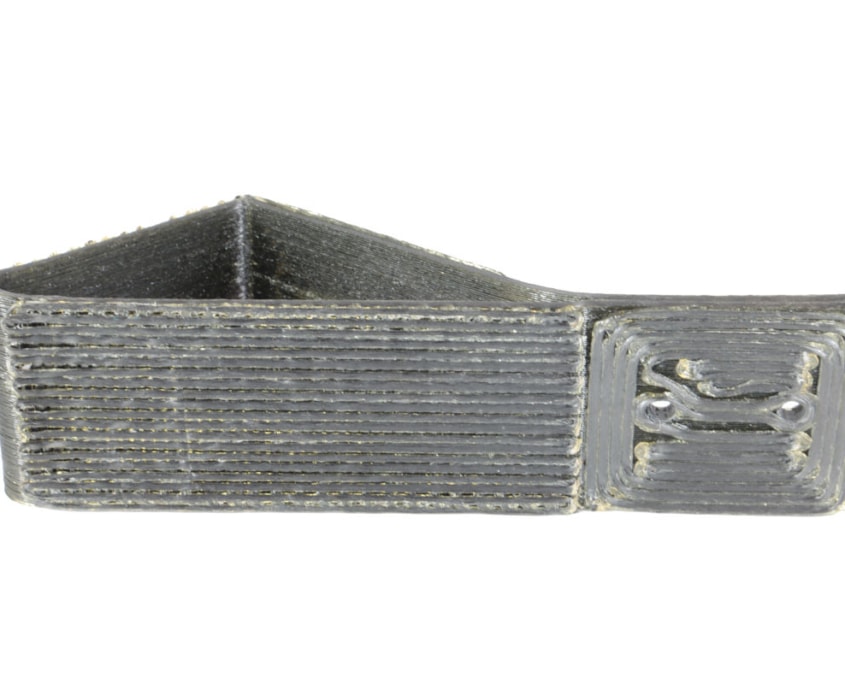

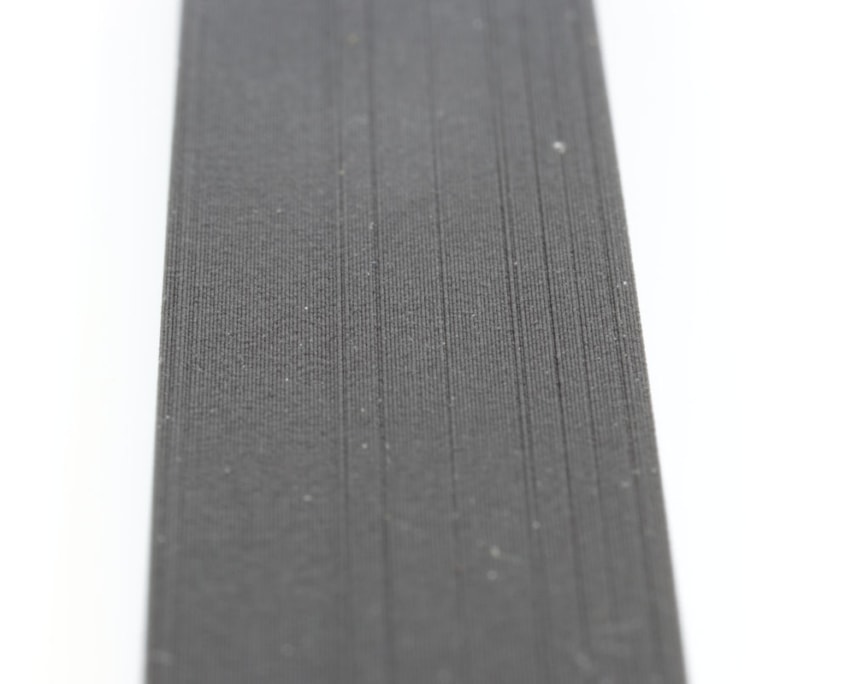

The study results provide an overview on the state-of-art of composite AM technology today and include the technologies of Continuous Fiber Material Extrusion, Continuous Fiber Thermoplastic Deposition, Continuous Fiber Sheet Lamination and Pellet Based Material Extrusion.

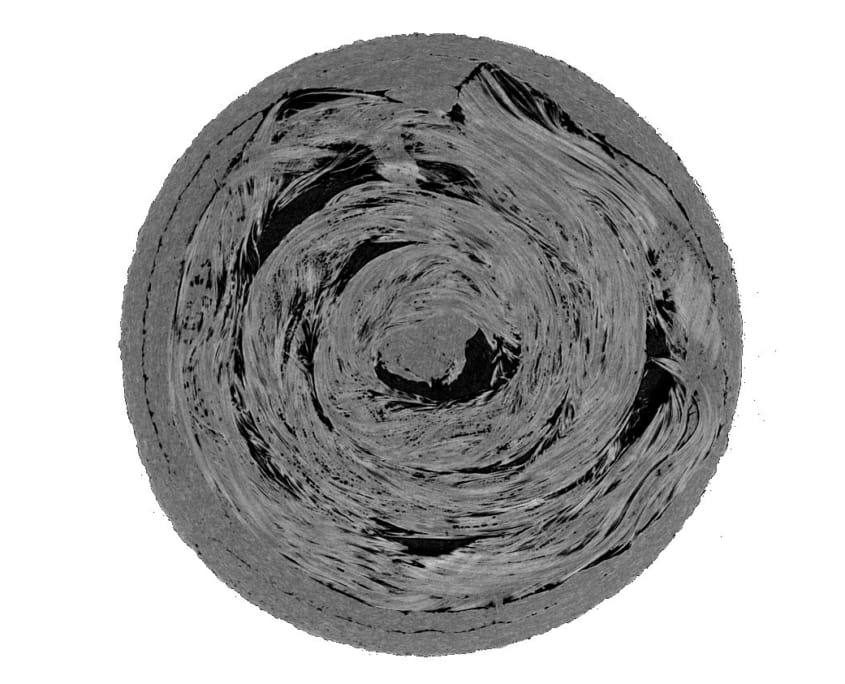

While some technology samples yielded tensile and bending results close to the expected and provided values from the vendors, others were deviating severly reaching only half of the expected tensile strength – an indication of the relatively low maturity of some of the tested technology. The empirical analysis through computer tomography imaging revealed the distribution and positioning of fibers with a part.

The economic and productivity analysis shows the high cost share of input material for continuous fiber composite technologies. Up to 95% of the total part cost are only due to the high cost of the material.