Ceramic Additive Manufacturing

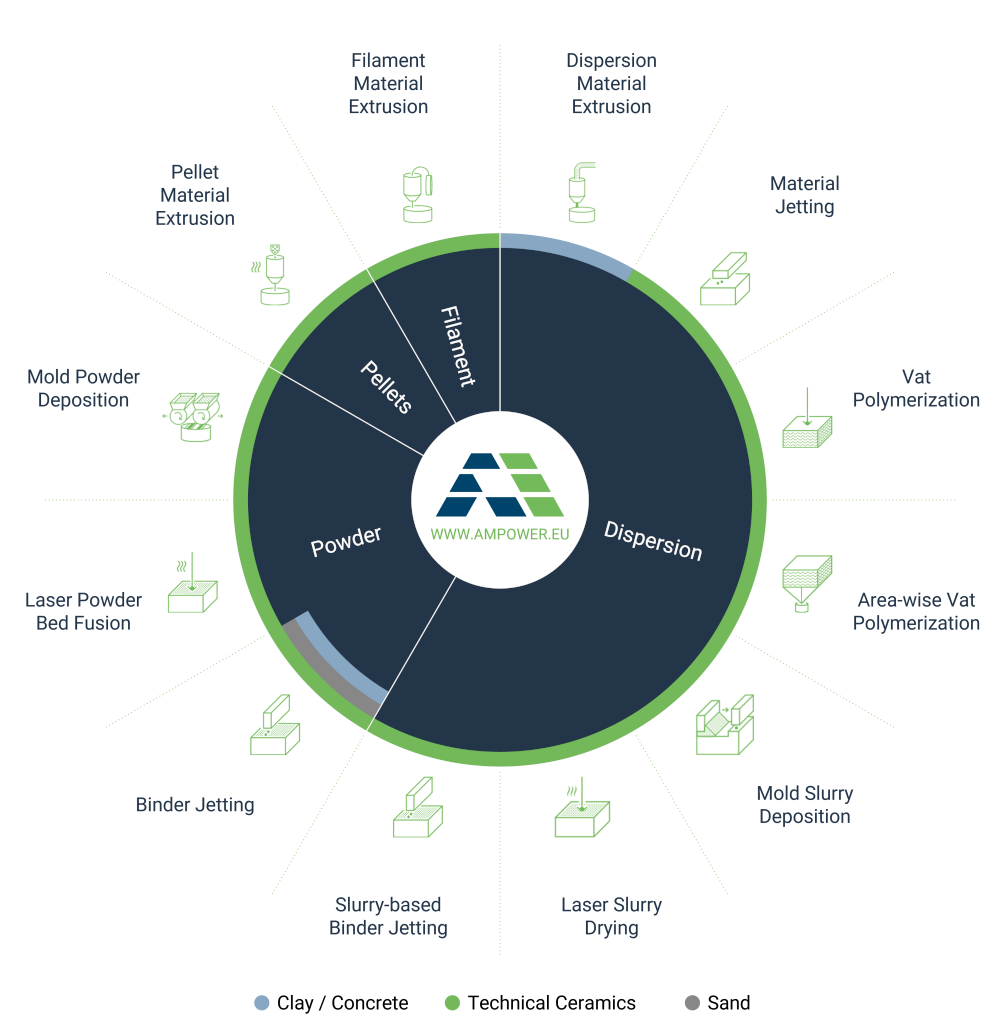

Ceramic Additive Manufacturing has made significant advancements, with Vat and Area-wise Vat Polymerization emerging as the most widespread technologies. Unlike metal Additive Manufacturing, most ceramic processes are sinter-based.

Vat Polymerization involves selectively curing liquid photopolymer resins using a light source, typically an ultraviolet (UV) laser or projector. The ceramic material is suspended in a liquid resin, and layer by layer, the cured resin solidifies to form the desired ceramic component. This process offers high resolution and is ideal for creating intricate ceramic parts with fine details.

While Vat Polymerization is the dominant technology, it’s important to note that the range of ceramic Additive Manufacturing processes is still relatively limited compared to metal or polymer 3D printing. However, ongoing research and development efforts are expanding the options available for ceramic Additive Manufacturing.

Ceramic AM beings to find applications in various fields, and companies and researchers need to familiarize themselves with the available technologies to select the most suitable one for each application. Staying updated with the latest advancements and considering the specific needs of the intended ceramic components is crucial as the technology continues to evolve.

Additionally, it’s worth noting that ceramic Additive Manufacturing is not limited to technical ceramics. Material extrusion is used to process clay and concrete for creating items like vases or even entire houses. In the casing industry, Binder Jetting of sand is highly industrialized for producing molds.

Strategic decision-making is essential when adopting ceramic Additive Manufacturing. Companies must assess the maturity of the different technologies, their suitability for the application at hand, and any necessary qualification requirements. While Vat Polymerization is prevalent, it may not always be the optimal choice for every scenario. Evaluating both short-term success and long-term planning is necessary when deciding on the right approach.

Download the Ceramic Additive Manufacturing technology landscape here

We provide the technology overview as a free download in PDF format. You are welcome to include the overview in your documents, stating the source.