Additive Manufacturing Business Strategy

Be successful with Additive Manufacturing

To find and employ the right strategy in Additive Manufacturing it is essential to determine the aim that is to be achieved. In Additive Manufacturing market can be split into two business segments that follow a different aim.

On one side providers of products and services in the AM supply chain have to compete and prevail against other providers. This includes AM machine vendors, feedstock producers, service bureaus but also auxiliary products and service providers. On the other side are the users. Across all verticals they strive to create unique selling propositions and increase customer satisfaction by using Additive Manufacturing

To achieve the business goals a sound strategy is required. Basis for a strategy is the analysis of the current situation on the supplier market. An approach based on a business model canvas is described in this study to derive a specific business proposal and hence develop a business strategy. This includes the essentials of a unique value proposition as well as the development of a go-to-market strategy.

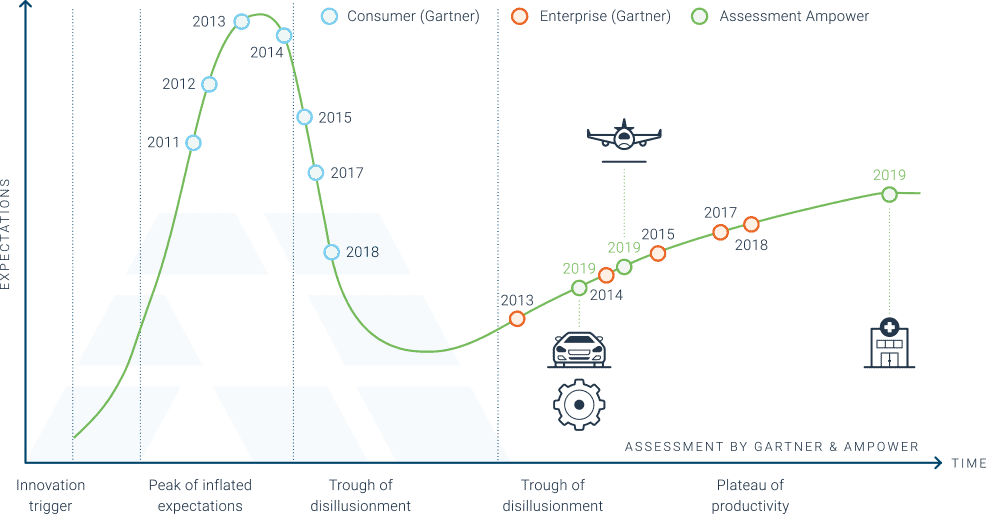

Every business faces the decision on choosing the right time to use a new technology. More and more enterprises begin to innovate their products and services with Additive Manufacturing that enables them to satisfy customer demands. Pioneers have the opportunity to shape the market, whereas late entrants have the luxury to base their decisions on a mature market. Ampower Insights provides an approach from understanding the customer benefit to decision making on using Additive Manufacturing.

Continuous innovations of solutions for the Additive Manufacturing process chain lead to an ever-evolving supply chain and enhanced competition. Small to medium sized enterprises dominated the AM market over the last decade. In recent years, many large companies became active in the AM business and began to offer products and services to their existing customer base in the supply chain.

In certain market segments the intensity of competition significantly increased. Over the last decade numerous players entered the market with Laser Powder Bed Fusion products and services that have a similar value proposition to the customer. Such low differentiation ultimately leads to, from the supplier point of view, undesired price competition.

The basis for determining the right way forward is to understand the current market and its competition. This supports in identifying opportunities that enable the supplier to evolve their products and services in order to add a unique value for the customer.

To develop such a strategy, there is several tools assist and provide a structure to define plans and actions that lead to a successful implementation.

The metal Additive Manufacturing market is a niche compared to the global market of metal products. However, the potential future market volumes are promising, and many companies are currently in the phase of market entry evaluation. Ampower Insight Vol. 5 presents an overview on the current status of the metal Additive Manufacturing industry and analyzes on how to derive a successful business strategy for suppliers as well as users of the technology.

The competition on the Additive Manufacturing supplier market is continuously growing. Feedstock suppliers, machine vendors, suppliers of auxiliary products and services as well as service bureaus strive for differentiation and a competitive advantage.

The basis for determining the right way forward is to understand the current market and its competition. This supports in identifying opportunities that enable the supplier to evolve their products and services in order to add a unique value for the customer.

To develop such a strategy, there is several tools assist and provide a structure to define plans and actions that lead to a successful implementation.

The following questions will have to be addressed and considered:

The medical device, aerospace or automotive industries come to mind that started to embrace AM and added 3D printing to their portfolio of production technologies. Increase of product performance and reduction of manufacturing cost are the main drivers for metal Additive Manufacturing adoption today.

The road to series production of metal Additive Manufacturing products is long. In the 2000s, announcements for serial applications were mainly found in medical and aviation industry. They identified applications with high benefits from adapting AM specific characteristics. Other industries such as tooling were also successful in utilizing the technology.

The commitment to an Additive Manufacturing technology as well as the time of market entry marks a significant decision. Over the past 20 years, metal Additive Manufacturing has been introduced successfully into many industries. First movers utilized their competitive advantage and placed products and services to secure a strategic market position. However, to enter

as first mover may not always be the best choice. Advantages as well as disadvantages come into play for first movers and followers alike and have to be assessed accordingly. With continuous improvement of machines and processes as well as inventions of new working principles, followers may gain the upper hand by adopting superior technology.

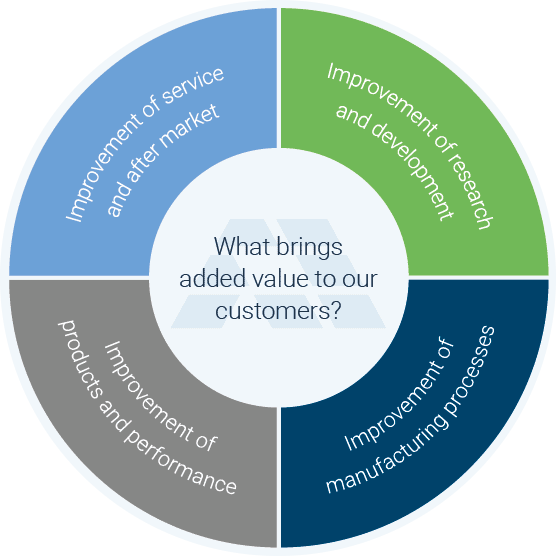

When formulating a business strategy, the central question should be: How do I satisfy the customer’s demands? To add further value to products and services, innovative technology such as Additive Manufacturing can be an answer. Following questions have to be addressed:

Identify opportunity in products and services with potential for added value

Identify suitable technologies by market screening – Additive Manufacturing may be a viable solution

Pilot study and knowledge transfer

Detailed market and scenario analysis

Implementation and qualification of Additive Manufacturing supply chain

The introduction of a new technology comes with changes that impact not only the shop floor but the whole organization. An analysis provides an insight on the importance of change management for implementation of Additive Manufacturing.

The use of Additive Manufacturing becomes successful, if products and services with added customer value are realized. A classification of four different fields is presented, where Additive Manufacturing enables such benefits. To identify potential applications, the bottom up and top down approaches are introduced.

Finally, the application has to be realized by the right technology. With a multitude and ever-growing number of metal Additive Manufacturing technologies, the options have to be analyzed and assessed. The presented technology map can help with a structured evaluation of the different Additive Manufacturing technologies.

In Volume 5 of the AMPOWER Insights, the topic of Additive Manufacturing Business Strategy is covered in detailed. This includes description of the tools described here combined with fascinating use cases. If you are interested in reading more, download the issue today!