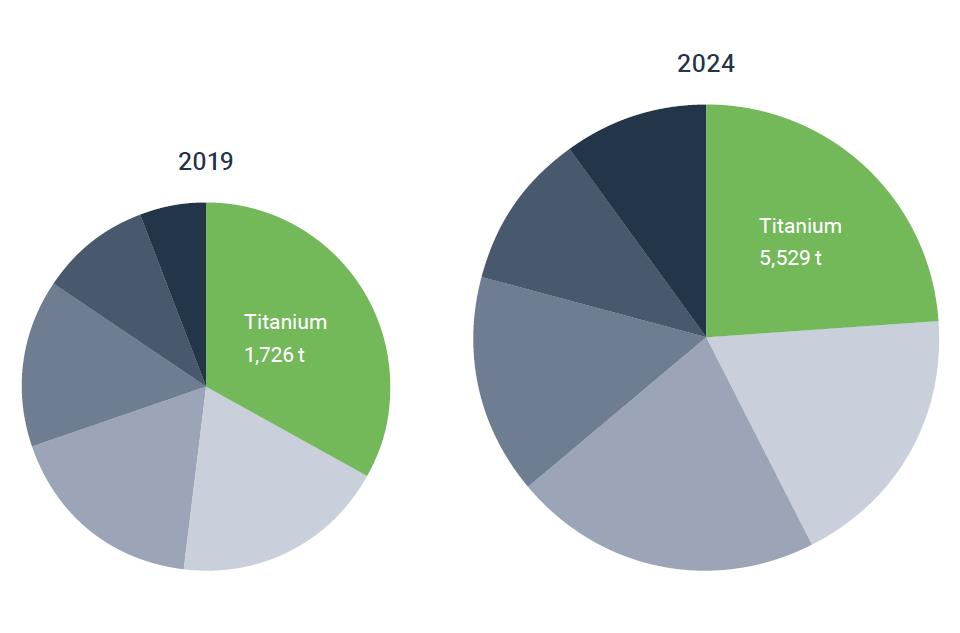

Titanium represents largest share of materials in AM

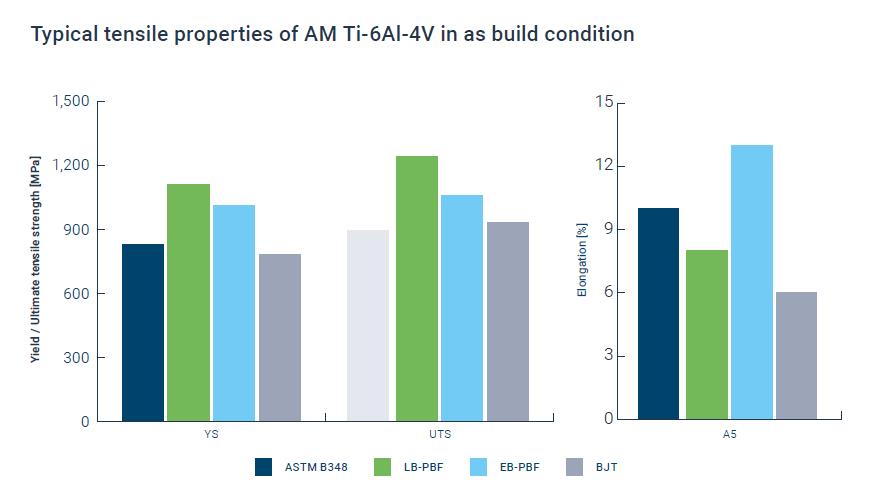

Titanium, specifically Ti-6Al-4V, is the most commonly used metal in Additive Manufacturing. Due to its high specific strength and biocompatibility it is used for demanding applications in aviation and the medical industry. Therefore the requirements regarding material performance for titanium AM parts are extremely high.

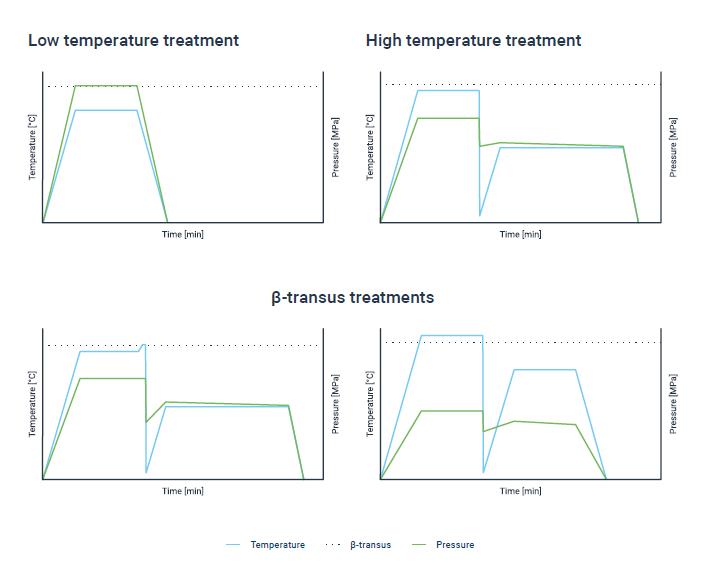

HIP cycles not optimized for AM

To increase the part performance hot isostatic pressing (HIP) is commonly used for highly demanding applications and has become a common post- process for titanium AM parts as well. However, the typically used temperature-pressure-cycles for AM are derived from HIP processes originally used for casting parts. Therefore they fall short to consider specific characteristics of AM materials which should be amplified or annihilated by the HIP process to optimize the resulting material performance.

Increasing part performance by optimized HIP cycles

Ampower Insights Vol. 7 PART 1 investigates AM specific material characteristics of LB-, EB-PBF and BJT which should be amplified or annihilated by an optimized HIP treatment and derives four specific temperature-pressure-cycles optimized for Ti-6Al-4V. In PART 2, to be published in Q3 2020, the resulting material performance of the optimized HIP cycles for all three AM technologies is presented. Resulting porosity, microstructure, tensile strength and fatigue properties will be investigated with over 200 specimen.