New polymer Additive Manufacturing technologies

Upcoming technology principles: potential and outlook

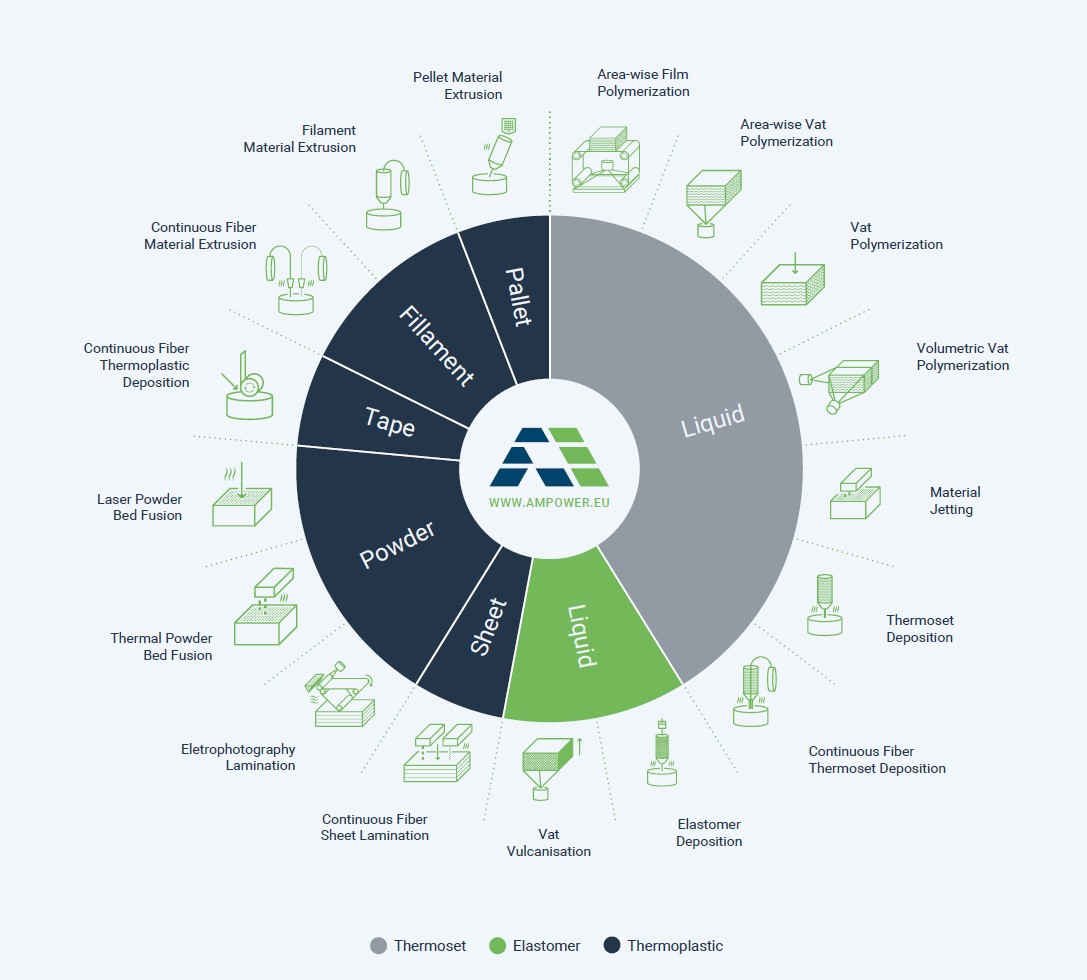

Polymer Additive Manufacturing is often associated with Material Extrusion, Laser Powder Bed Fusion or Photopolymerization technologies. However, there are 17 different technology principles identified today. While some of these principles are in an early development stage, many are successfully used in industrial set-ups or are expected to find a viable niche as manufacturing technology.

To be successful in using polymer Additive Manufacturing, it is crucial to choose the right manufacturing technology, established or new. The 11th volume of AMPOWER Insights provides an overview on upcoming technology principles and assesses their potential.

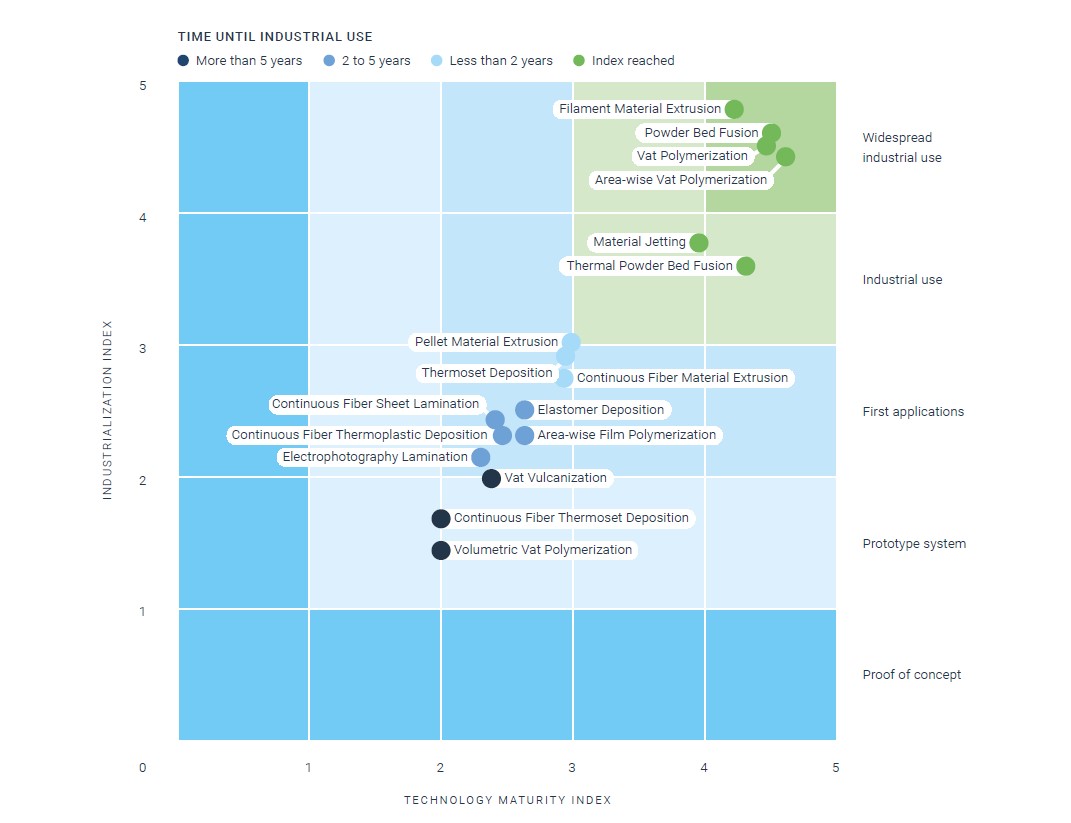

To evaluate the state of the art of polymer Additive Manufacturing, AMPOWER has developed a methodology – the AM Maturity Index. This index provides the user with a tool for quick assessment based on the technology as well as industrialization maturity. While the technology index evaluates the current production process capability and machine concept, the industrialization index reflects the existing knowledge base and availability in the market.

The reviewed technologies are clustered into different groups. The first group are volumetric technologies from vendors such as XOLO and READILY. The second group covers high viscosity photopolymer technologies which were announced by BCN3D and CUBICURE in 2021 and 2022, respectively. Both technologies utilize high viscosity photopolymers to enhance material properties combined with a high throughput approach.

Image courtesy of INKBIT

The third group comprises powder technologies. Included are EVOLVE with its Electrophotography Lamination Process and IMPOSSIBLE OBJECTS. With 3DEUS DYNAMICS and SPECTROPLAST there is another group of elastomer technologies able to process silicone material for consumer goods as well as medical applications.

Last but not least new thermoset technologies are commercialized by MASSIVIT and INKBIT. MASSIVIT large-scale printer aims at decreasing lead time in mold production. INKTBIT combines Material Jetting with process control and new material developments to push its use in production environment. Today, AMPOWER rates these aforementioned technologies at a relatively low industrialization and technology maturity level. However, the high potential may yield a fast shift, if industry adoption can be achieved.