About the guideline

This guideline is a collection of design rules developed by industry leaders in the field of Powder Metallurgy and sinter-based Additive Manufacturing. It is made possible by the gathered experience of more than 12 companies and institutions who contributed their knowledge into this continuously improving guideline. Its purpose is to enable designers, engineers and students to leverage the full potential of sinter-based Additive Manufacturing technologies. We want to thank all contributors for their generous input and hope that many new users of sinter-based Additive Manufacturing technologies benefit from this guideline.

Process principles

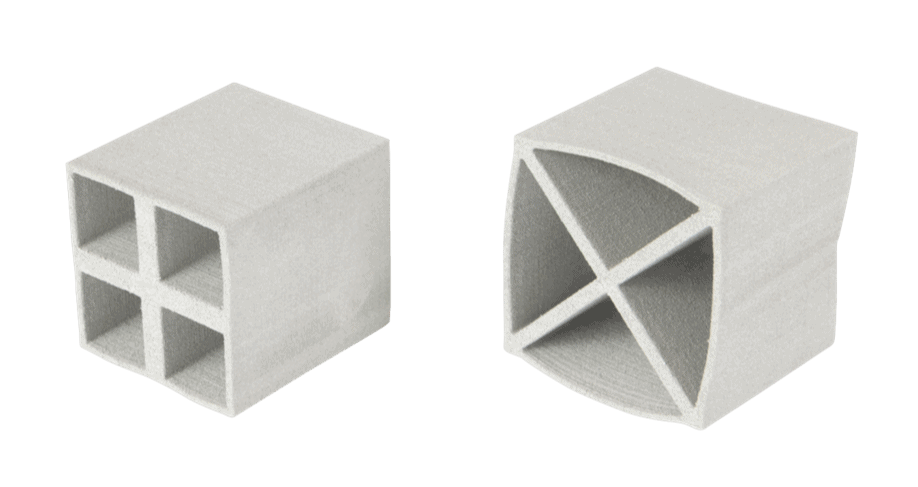

The process chain of sinter-based technologies differs from other AM Technologies. Especially the post-printing processes (debinding and sintering) are crucial to achieve the intended mechanical properties. The guideline will provide an in-depth overview on the process chain, depowdering, debinding and sintering, as well as the effects such as shrinkage and scaling, baseplate friction during sintering, distortion and cracking. Furthermore, the most improtant cost-drivers are discussed.

Design guideline

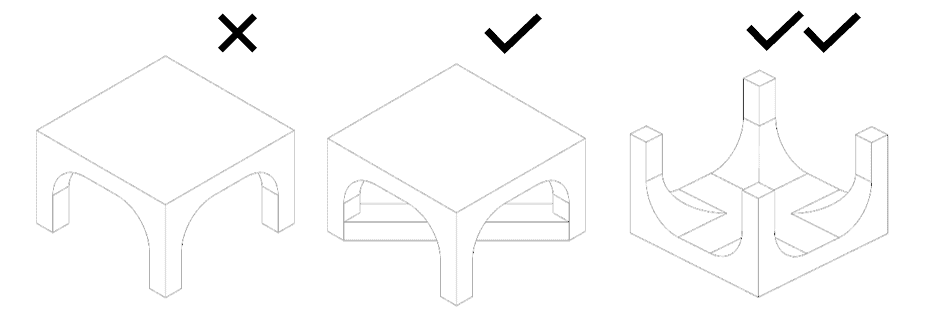

The design of sinter-based technologies such as Metal ME and BJT are not only limited by the printing process. The debinding and sintering are critical for the characteristics of the part and must be considered for an appropriate design.

This design guide will provide an overview of relevant features to ensure a proper part design regarding debinding, sintering and printing requirements. If the rules are not applied, parts may suffer from distortion, cracking, delamination and/or collapse, as illustrated by examples on the following pages.

Download the complete study

Training course

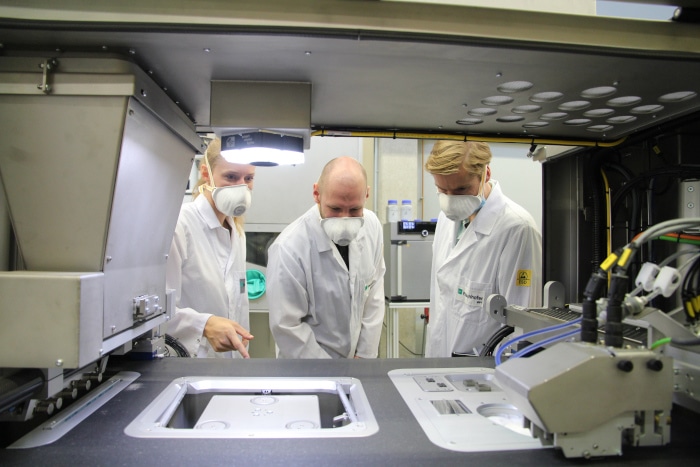

Hands-on Binder Jetting training

Metal Binder Jetting is one of the most promising metal Additive Manufacturing technologies with a high potential for low cost and high-volume digital manufacturing. However, the complete process chain of Binder Jetting is highly complex and the supply chain is still developing. AMPOWER created a unique binder jetting training course in cooperation with the FRAUNHOFER IAPT in Hamburg. Participants will learn the theoretical basics accompanied by a comprehensive hands-on session through the complete process chain.