Metal Binder Jetting Implementation

A strategic guideline to implement Metal Binder Jetting

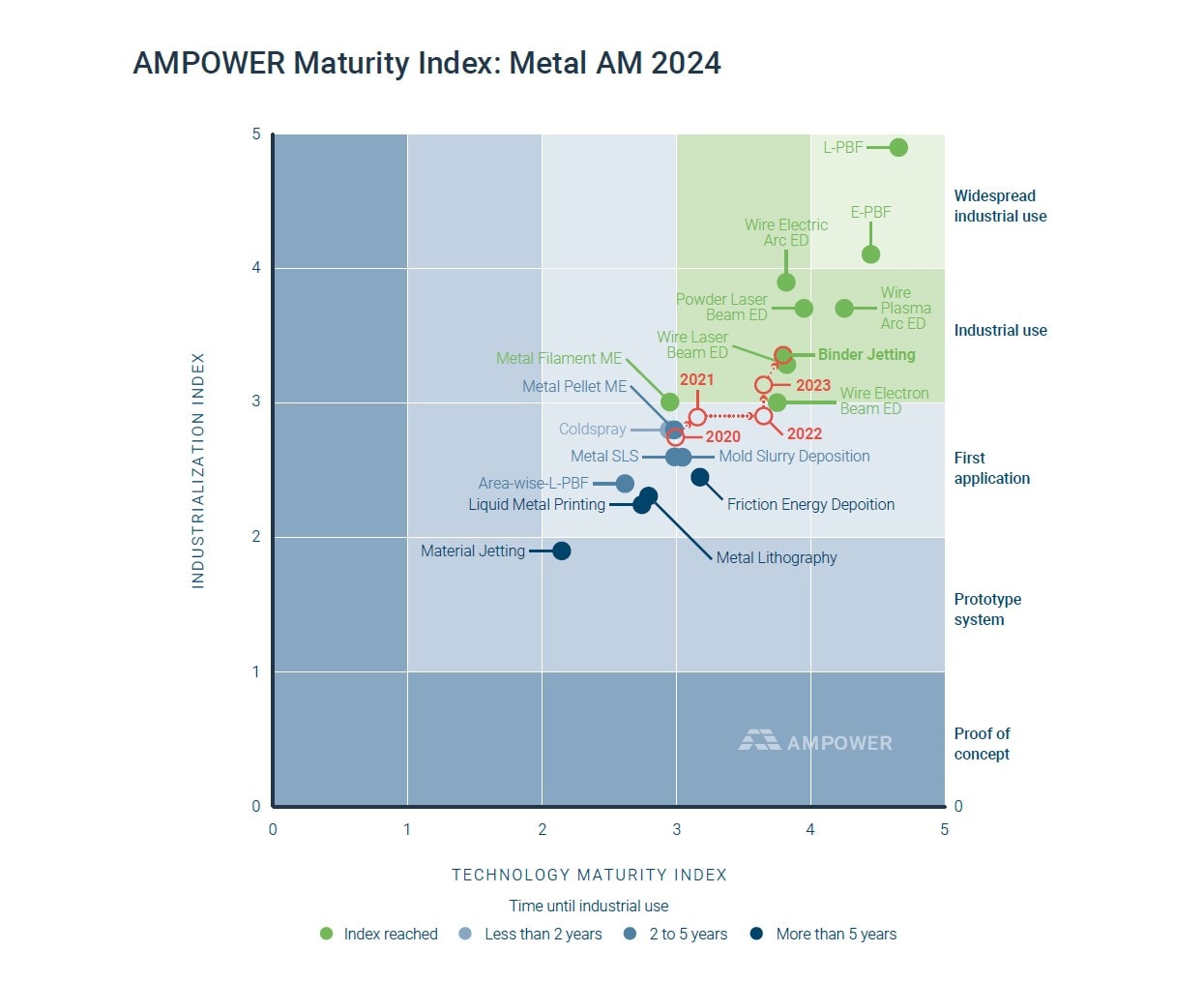

To evaluate different AM technologies AMPOWER has developed a model to describe their maturity based on two indices. The Industrialization Index and the Technology Maturity Index describe and compare the adoption rate and its capabilities of each AM technology in an industrial environment. Both indices are crucial for evaluating the overall status of a technology. Metal Binder Jetting continuously moved forward in the Maturity Index over the last couple of years.

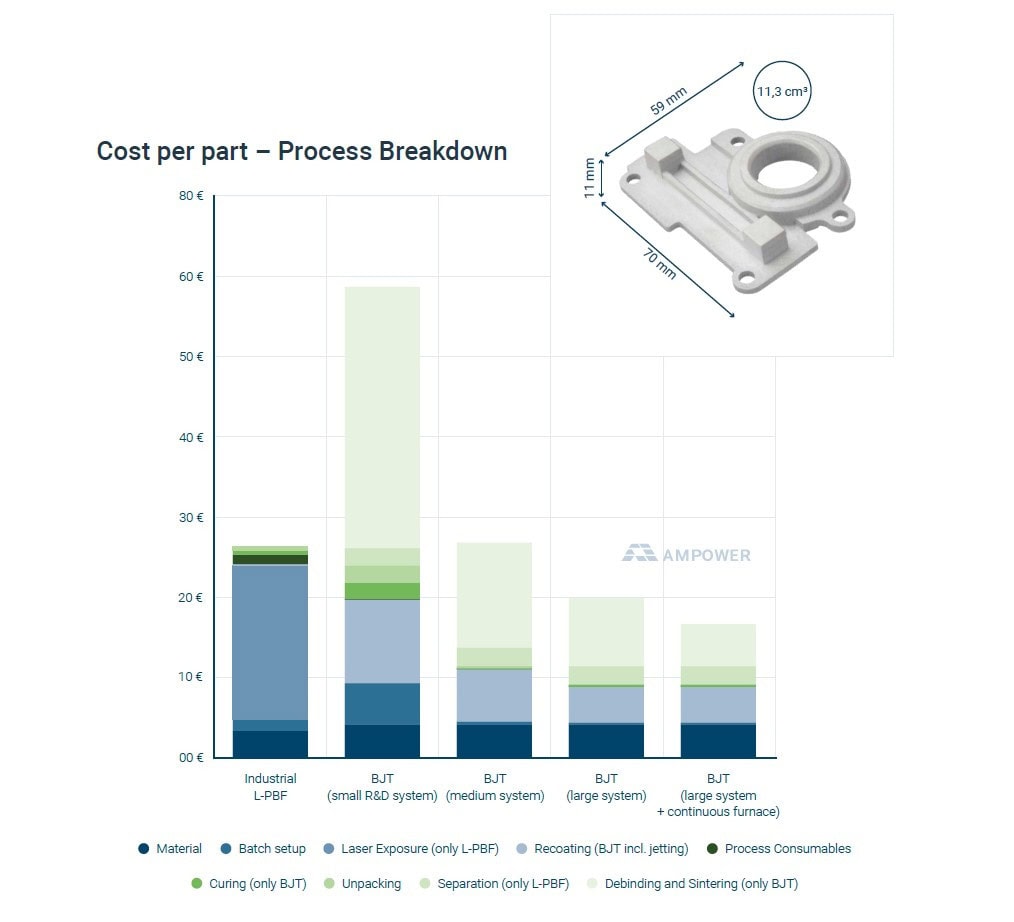

Considering direct production or as-printed cost, the cost of additively manufactured parts are significantly dependent on the equipment investment and feedstock price. The share of cost of these factors are predominantly influenced by the part’s geometry. The part volume determining the material consumption and the part size influencing machine utilization and print time.

Regarding equipment cost, Binder Jetting requires a special sintering furnace, resulting in a relatively high initial investment compared to other AM processes. The following cost calculation provides a basic comparison between L-PBF and different BJT system sizes. Not in the scope of the calculation are advanced post processing (machining, surface treatment), ongoing quality assurance, company overheads, initial qualification investment as well as application design and optimization.

Qualified equipment and validated processes are a prerequisite for production in regulated environments. Specifications describe the part, material and process. The development of these specifications is the initial step in the implementation of a new manufacturing technology.

The machine qualification is a series of inspections and tests to verify that equipment meets requirements. This includes procedures and documentation for the acceptance tests (at factory or on site) as well as installation, operation and maintenance of the machine. The requirements typically derive from industrial standards, manufacturer and customer specifications. The method of Installation, Operational and Performance Qualification (IQ, OQ, PQ) used in medical industry has been proven to be well adaptable to AM systems.