Quality in Additive Manufacturing

Best practices for quality management in Additive Manufacturing

Additive Manufacturing is entering industrial serial production. Especially in regulated industries such as aviation and medical, the need for internationally accepted standards and proven practices for machine qualification is continuously growing. To meet this demand, Ampower Insights Vol. 4 presents a comprehensive approach and best practices to establish a qualified production environment and gives an overview on standardization efforts and published standards.

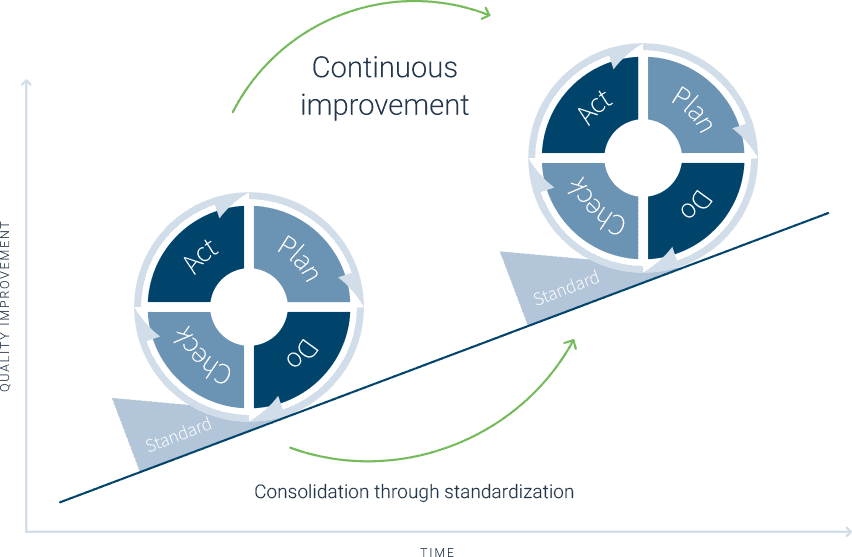

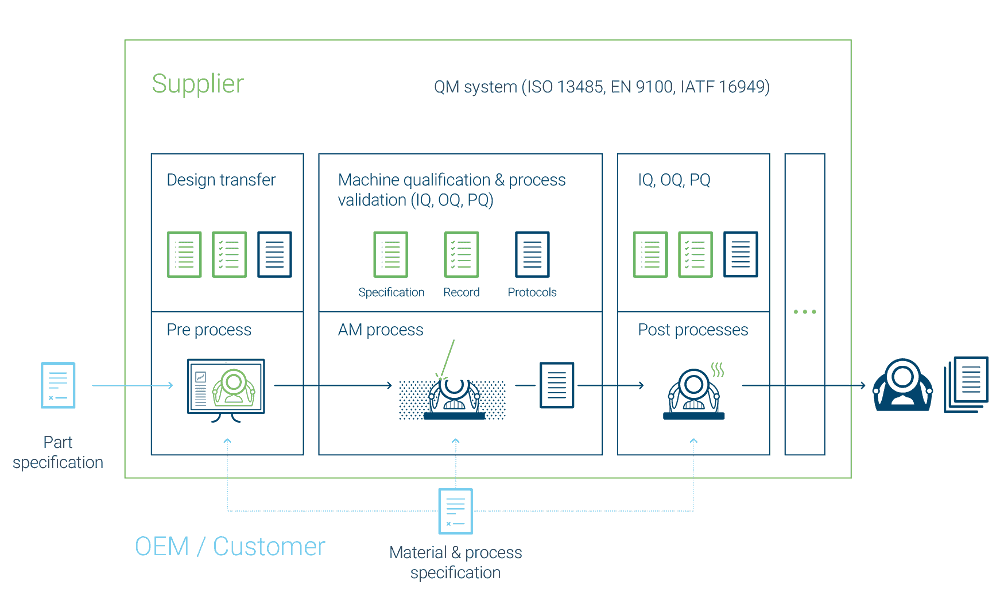

A thorough machine qualification is the essential foundation for a successful implementation of manufacturing systems in regulated industries. Due to the pioneering role of medical applications, the methodologies from the Global Harmonization Task Force for machine qualification including Installation, Operational and Performance Qualification (IQ, OQ, PQ) have been widely adapted in the AM industry. Ampower Insights presents the requirements as well as documentation and testing efforts for each of the qualification steps and highlights best practices for a successful implementation of Additive Manufacturing.

Ampower Insights highlights the current landscape of existing AM standards and committees responsible for standardization. To illustrate this the route to developing international standards within the framework of the ISO TC 261 and ASTM F42 committees is described. Furthermore, a detailed look on quality management in Additive Manufacturing shows that additionally to existing quality management certifications such as EN/AS 9100 and ISO 13485, the industry is demanding and developing AM specific certifications such as the NADCAP certificate.

The study closes with representative statements of AM experts from an early adopter medical company to a high-volume automotive manufacturer on the state of qualification and standardization in their respective field. The aggregated results suggest that a strong personnel and monetary commitment and focus is required to successfully implement a qualified AM production. Ampower Insights Vol. 4 gives a comprehensive view on qualification methodologies and the state of standardization for Additive Manufacturing technologies.

“Many business cases for Additive Manufacturing with laser beam powderbed fusion technology are in regulated industries such as aviation or medical. However, the current lack of standards and knowledge on AM qualification increases the threshold for companies to adapt the technology. Therefore Ampower partnered with Trumpf to conduct an extensive study and present a comprehensive qualification approach and best practices to establish a qualified production environment.”

Dr. Eric Wycisk

Managing Partner at AMPOWER

“In the field of Additive Manufacturing, TRUMPF sees great opportunities not just for itself but for German industry overall. Qualification, however, proves to be a challenging issue for the end-user. By demonstrating the qualification process on TRUMPF’s 3D printer TruPrint 3000 and sharing best practices for standardization, the study we conducted with Ampower assists end-users to successfully apply Additive Manufacturing in their production and contributes to the ongoing technological development in general.”

Dr. Thomas Fehn

General Manager Additive Manufacturing at TRUMPF