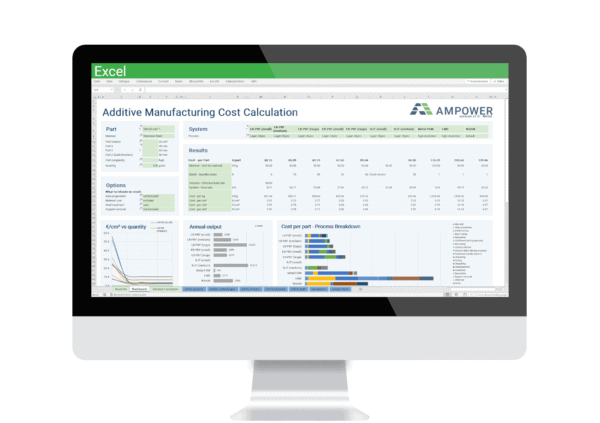

Cost Calculator

4.900,00 €

excl. VAT

Calculate manufacturing cost of metal additive manufacturing parts based on their volume, bounding box, complexity and quantity in a wide range of technologies:

- Metal L-PBF (small, medium, large machine)

- E-PBF (also known as EBM, small and large machine)

- Binder Jetting (small and medium machine)

- Metal Material Extrusion

- Powder Laser Energy Deposition (als known as LMD)

- Wire Arc Energy Deposition (also known as WAAM)

- Polymer L-PBF (also known as SLS, small and large machine)

- Polymer Material Extrusion (also known as FFF or FDM, desktop and industrial machine)

- T-PBF (Also known as Multi Jet Fusion)

Metal materials include Stainless Steels, Nickel-based Alloys, Titanium-based alloys and Aluminum-based alloys.

Polymer materials include ABS and PA12 .

Market pricing includes

- Metal L-PBF Stainless Steels, Aluminum- and Titanium-Alloy

- Polymer L-PBF PA12

- T-PBF PA12

- Polymer Material Extrusion ABS

Compare up to 10 different Additive Manufacturing machine combinations and get a complex calculation output such as:

- EUR/ccm over quantity

- Annual throughput

- Process chain cost break down

- Production time

- Market pricing

Break down the process chain into

- Material

- Data preparation

- Machine setup

- Printing

- Curing (sinter-technologies)

- Unpacking

- Sintering (sinter-technologies)

- Heat treatment

Complete Excel-based, all values can be individualized with basic Excel skills.

Calculation based on real reference build times.