Study description

Current market reports for metal additive manufacturing are focused on the current state of the industry. Forecasts based on historical data can only foresee already anticipated developments. This study is aimed beyond that scope and assesses the potential market size according to current and future production costs of additive manufacturing.

In this study, AMPOWER presents an objective and independent analysis beyond the current AMPOWER Report data. By analyzing nine material groups in seven industries, AMPOWER shows how decreasing production costs can increase the potential metal AM market.

Study results

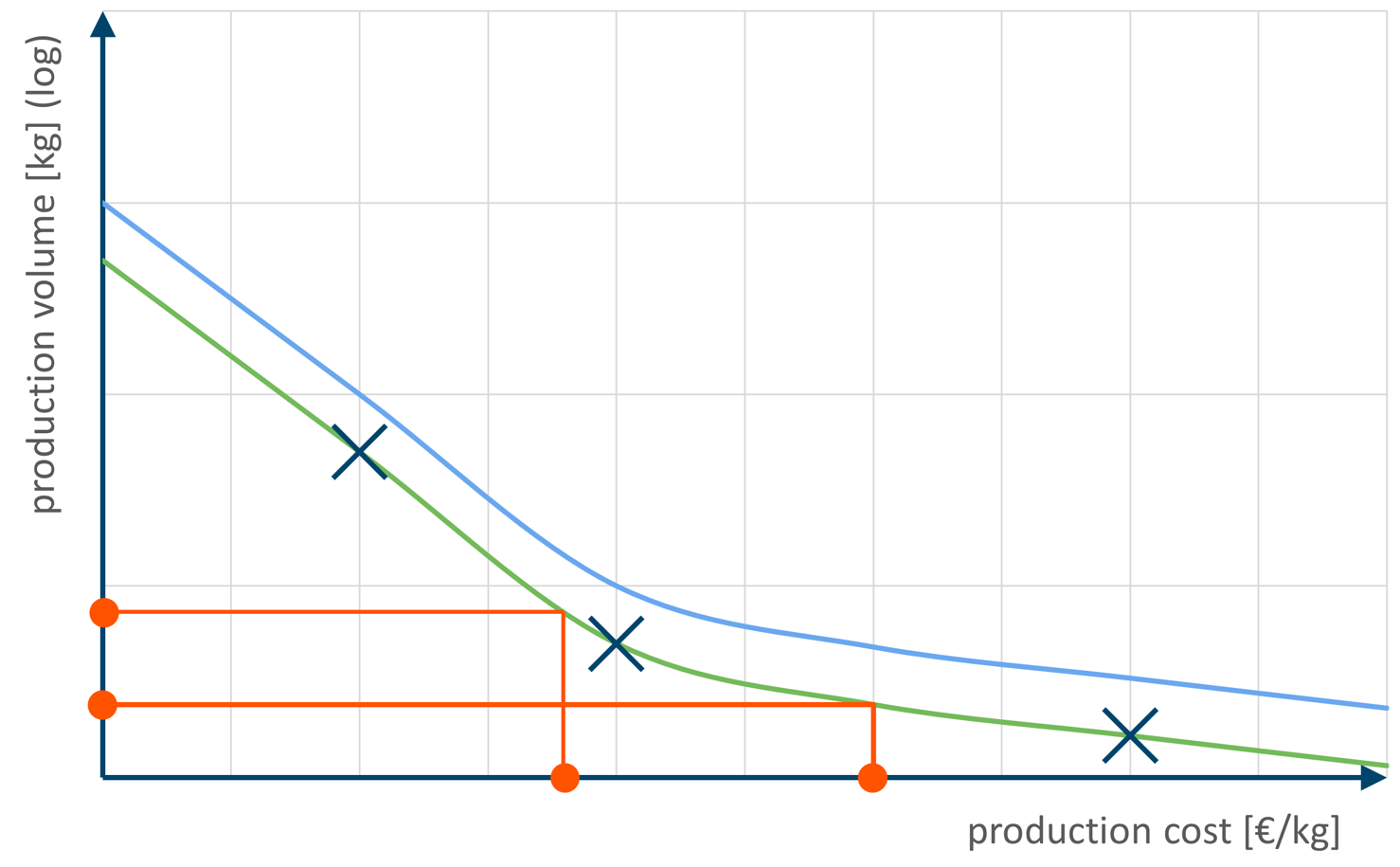

Metal AM competes with other production technologies, offering advantages like functional integration, performance, and tool elimination. The key metric for comparison is cost per unit size (e.g., EUR per kg), allowing objective decisions in the design phase. Plotting production cost against material consumption estimates the addressable market based on cost per unit. Adoption rate can be assessed by comparing this estimate with current AM material consumption.

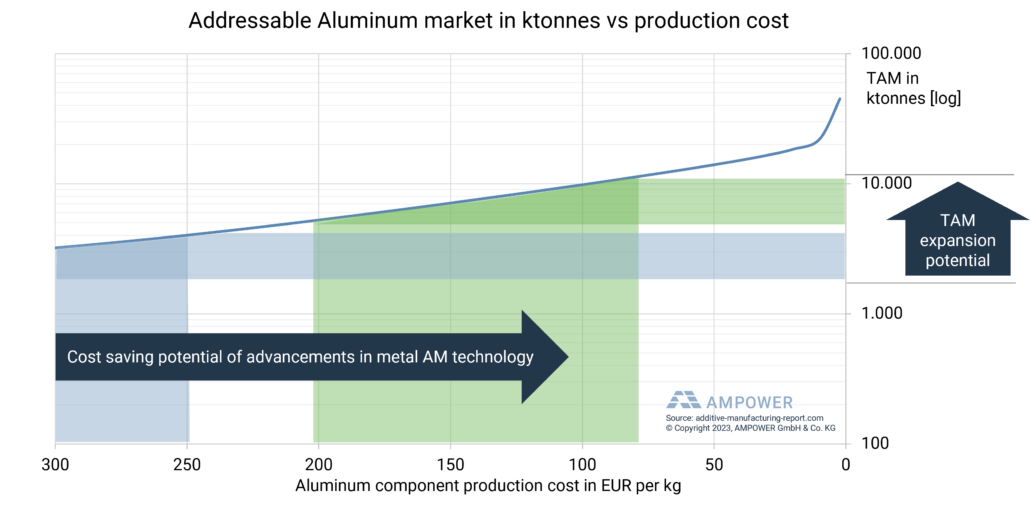

In aluminum AM applications, component production costs are approximately 250 to 300 EUR per kg. The AMPOWER Report indicates for 2022 an annual consumption of around 600 tons of feedstock (powder, rod, etc.), reflecting an adoption rate of only 0.02% of the addressable market, currently at 3,000,000 tons.

Future technological progress will boost productivity and cut costs, expanding the addressable market. Considering potential AM productivity improvements by 2030, a cost reduction to 100-200 EUR per kg is anticipated. At this point, AM will compete broadly with machining, investment casting, and, to some extent, sand casting. The addressable market for metal AM and aluminum materials is expected to double to 6,000,000 tons by 2030.

The full study, available on request, provides a detailed analysis of the addressable market for Additive Manufacturing of Stainless Steel, Titanium alloys, Aluminum alloys, Tool Steel alloys, Nickel-based alloys, and Cobalt Chrome materials in relation to manufacturing costs.