Study description

Copper and its alloys offer excellent material properties in terms of electrical and thermal conductivity. Believed as one key material supporting the electrification of transportation, AM can play a significant role by enabling innovative applications.

Out of the 20 different metal AM technologies AMPOWER categorizes today, vendors of half a dozen technologies have introduced processing of copper. Suppliers of another 6 technologies invest into research to make the material available for their process.

AMPOWER conducted the technology study to assess the maturity of processing copper materials with Additive Manufacturing. The analysis includes an evaluation of the specific process chain including the digital processing, the cost and productivity, materials properties, among others.

AMPOWER started to conduct the study in the second half of 2021 and finished in 2022.

Study aim

The study results provide an overview on the state-of-art of copper AM technology today and include the technologies such of Powder Bed Fusion with lasers of different wavelength, Powder Bed Fusion with electron beam or Cold Spray. A major focus will be on sinter-based technologies, such as Binder Jetting, or Metal Material Extrusion.

Out of the 20 different AM processes today, the study included empirical analysis of 6 technologies, as well as additional sub-types. The theoratical assessment considers the technology maturity and availability, advantages and limitations of the processes, as well as an extensive look at the cost structure.

Empirically, the resulting electrical and thermal conductivity properties were studied. Independent measurements ensure unbiased results.

Study results

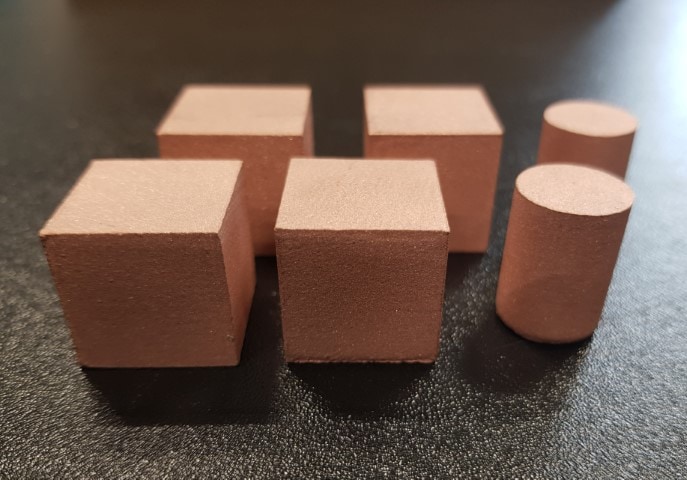

The empirical analysis included sample sets from 11 different vendors and testing of electrical conductivity, thermal conductivity, density and metallography. Part of the analysis was studying the effect of a HIP process. The electrical conductivity measurements considered the parameters of building direction and surface quality. Direct AM processes L-PBF and E-PBF yielded overall high conductivity than the sinter-based technologies. However, some direct processes were surprisingly exhibiting significant lower values than expected.

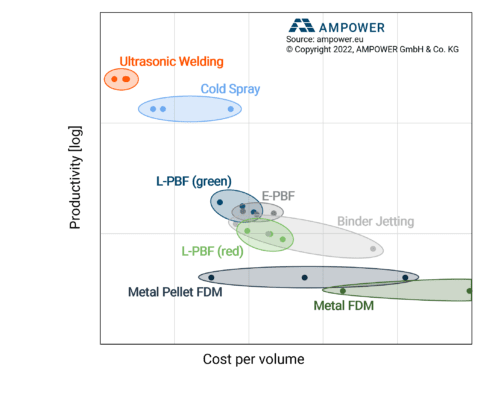

For the assessment of the cost structure, the study relied on the AM specific cost calculation model developed and refined by AMPOWER over the past years. The model was fed with real world parameters, typical exagerated data sheet parameters were omitted.

Ultrasonic Welding and Cold Spray showed overall leading characteristics considering the cost and productivity. The specific limitations in freedom of design have to be considered. Binder Jetting is in a similar cost and productivity range to PBF today.