Introduction

In general, cost in production is a key success factor. This holds also for Additive Manufacturing, a technology with unmatched potential compared to traditional manufacturing. However, AM has to compete with conventional technologies. Only if the added value of the AM product or service outweighs the potential cost difference, it can become a successful business case. The prediction of cost becomes of high importance during the development phase of a product. To evaluate the business case and to decide on Make or Buy, there is a lack of knowledge on the real cost of AM.

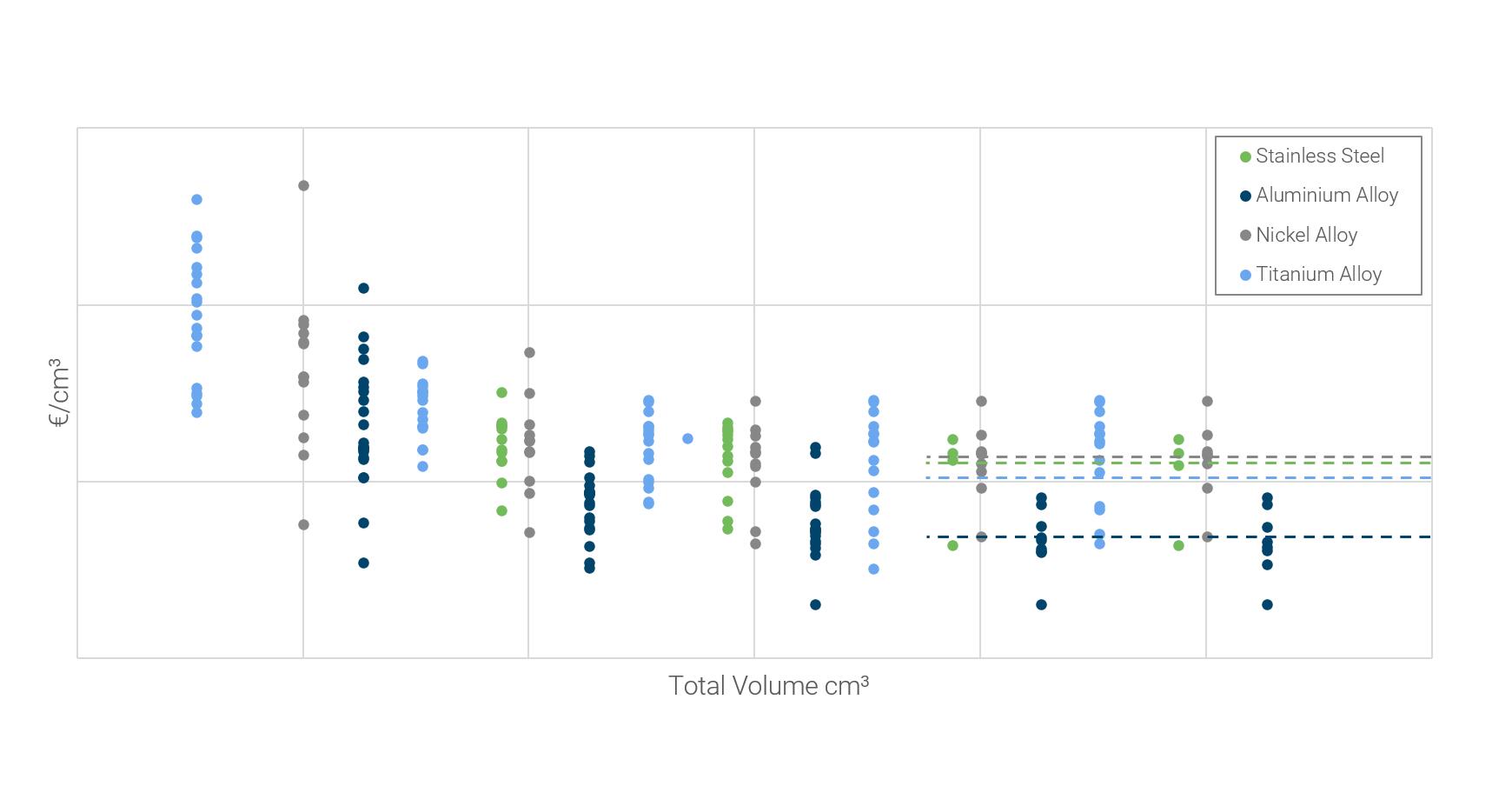

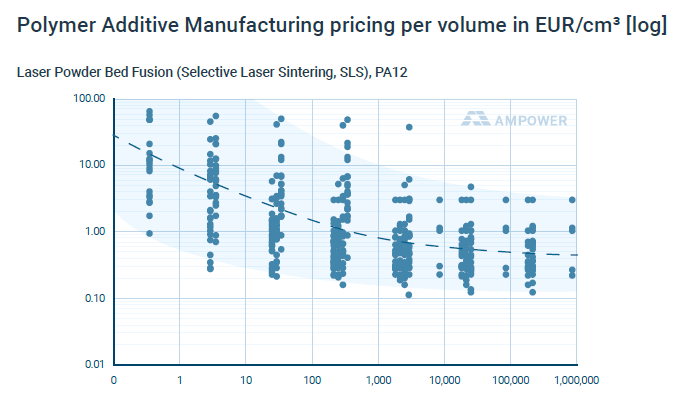

AMPOWER conducted a market study on actual costs in Additive Manufacturing to provide an overview on the status quo and to answer several key questions. Firstly, how much does AM cost internally and externally today, how will these costs develop in the future? How do cost models change with regards to increasing quantities vs. traditional technologies?

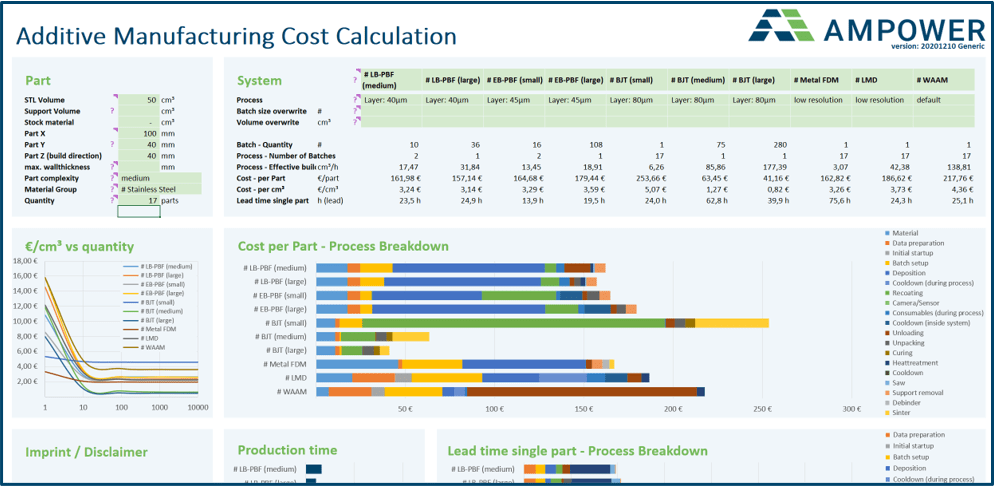

The Cost Calculation Tool

The result of the study was the AMPOWER Cost Calculator. The AMPOWER Cost Calculator is the most comprehensive tool to assess the total cost of ownership of Additive Manufacturing parts. Based on countless production build protocols and extensive research, the tool enables you to compare different technologies and get transparency about the real cost of Additive Manufacturing parts.

AMPOWER offers to support users and suppliers of the Additive Manufacturing industry by making business decisions based on cost knowledge. Evaluate your internal business cases and take into account future innovations that will lead to further cost reduction for Additive Manufacturing. Suppliers can benefit from cross-technology insights to evaluate their product pricing and understand cost sensitive development potentials for their technology. Users of the tool will learn about the real costs of AM today. Furthermore, you will gain the knowledge to make the decision for the most cost-efficient technology as well as for choosing make vs. buy.