Study description

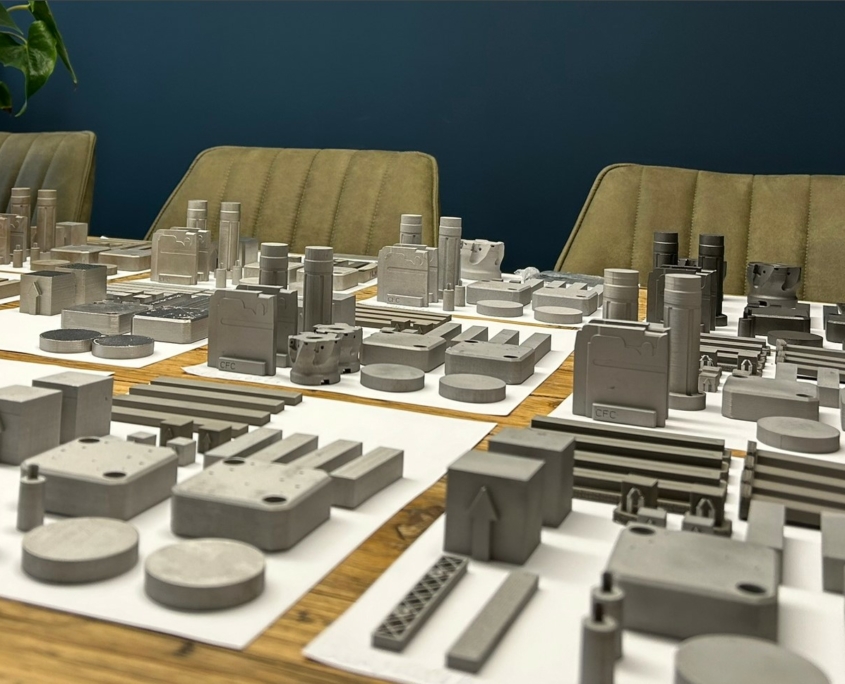

Tool steels are particularly resistant steels, offering excellent material properties regarding hardness, toughness and wear resistance. These characteristics also make the machining of these materials challenging. Through near net shape production and the integration of conformal cooling channels, AM can both simplify the production process and increase the part performance.

The study provides a state-of-the-art overview of tool steel processing using AM technologies. In addition to laser powder bed fusion, the study also covers sinter-based technologies such as Binder Jetting, Metal Material Extrusion and Metal Selective Laser Sintering. Overall, 8 different tool steels and 18 process and material combinations are studied. The individual processes offer different process-related advantages and limitations when processing the materials and with regard to design freedom. A total of 8 different tool steels and 18 process and material combinations are examined.

AMPOWER is conducting the technology study to assess the maturity of processing tool steels with additive manufacturing. The analysis includes an assessment of the specific process chain, including digital processing, cost and productivity, material properties and other factors.

Study aim

The study provides a state-of-the-art overview of tool steel processing using AM technologies. In addition to laser powder bed fusion, the study also covers sinter-based technologies such as Binder Jetting, Metal Material Extrusion and Metal Selective Laser Sintering.

The study empirically analyzes 5 technologies and further subtypes. The theoretical evaluation takes into account the maturity and availability of the technology, the advantages and limitations of the processes and a comprehensive look at the cost structure.

Empirically, properties such as microstructure, hardness, fracture toughness, wear resistance and surface roughness are examined. Independent measurements guarantee unbiased results.