Study description

Wire-based Directed Energy Deposition (DED) has established itself as a key technology for producing large-scale metal components, combining high deposition rates with efficient material use. Among its variants, laser-based wire DED systems are gaining traction in sectors where build size, productivity, and metallurgical control are critical.

This AMPOWER study provides a structured investigation into the current state of the art in wire DED. Nine distinct Wire DED technology variants from multiple suppliers were selected for independent empirical testing, ensuring representative coverage of available solutions on the market. The included technologies are Wire Laser, Wire Electric Arc, Wire Electron Beam and Wire Plasma Arc. The scope of the study also includes a commercial assessment of both capital investment and ongoing operating costs, as well as an evaluation of the digital process chain, wire feedstock requirements, and the existing standards landscape.

Study results

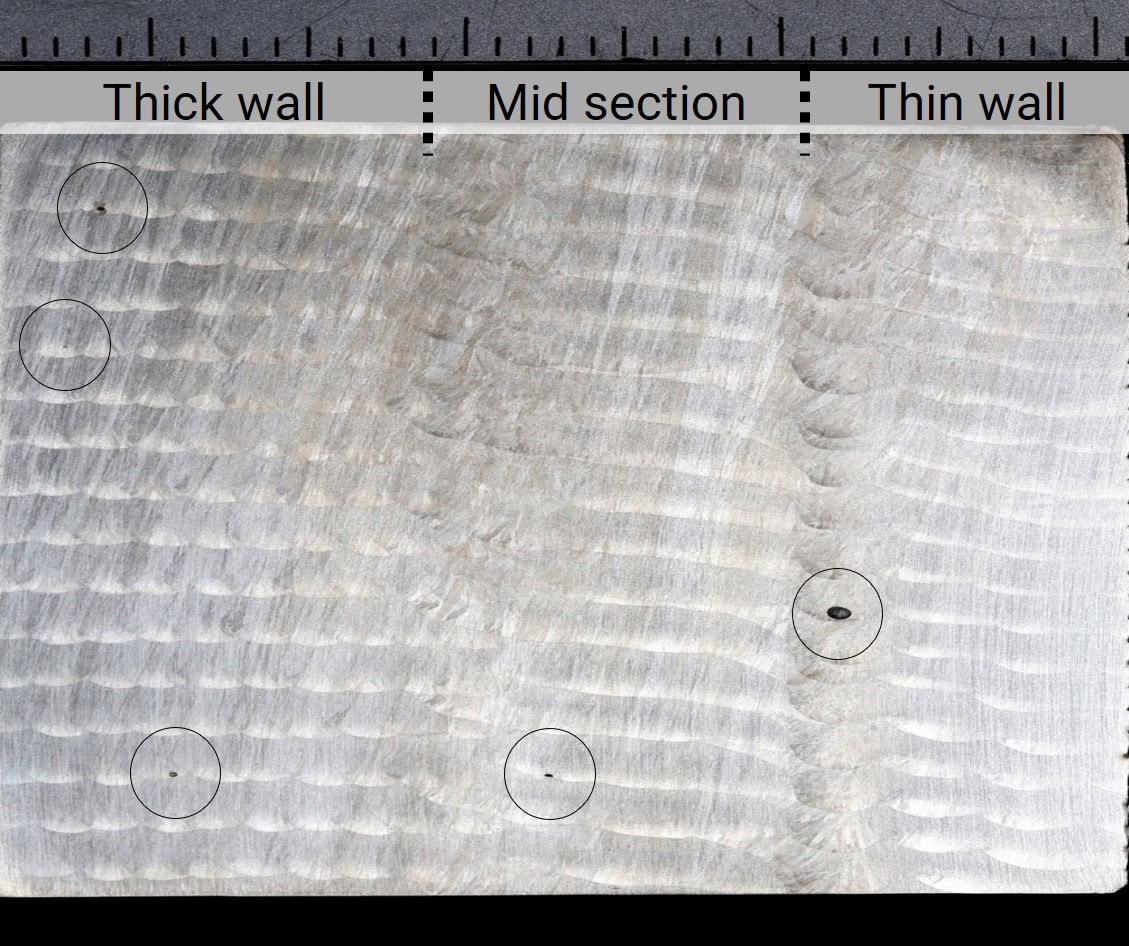

The study investigated nine Wire DED technologies under standardized testing conditions. Parameters examined included build accuracy, deposition rate, build quality, and process stability. Each system was benchmarked to provide a consistent basis for comparison.

In addition to technical performance, the study evaluated investment and operating costs, identifying the major cost components across the different systems. The complete digital process chain was assessed, from design preparation to machine control, to understand workflow efficiency and integration potential.

The investigation also included an analysis of wire feedstock as well as a review of the applicable standards and their relevance to industrial adoption. Together, these results provide a comprehensive picture of the technological and commercial status of Wire DED and their sweet spots in application.