Watch the video tutorial

Calculate Additive Manufacturing cost for your part

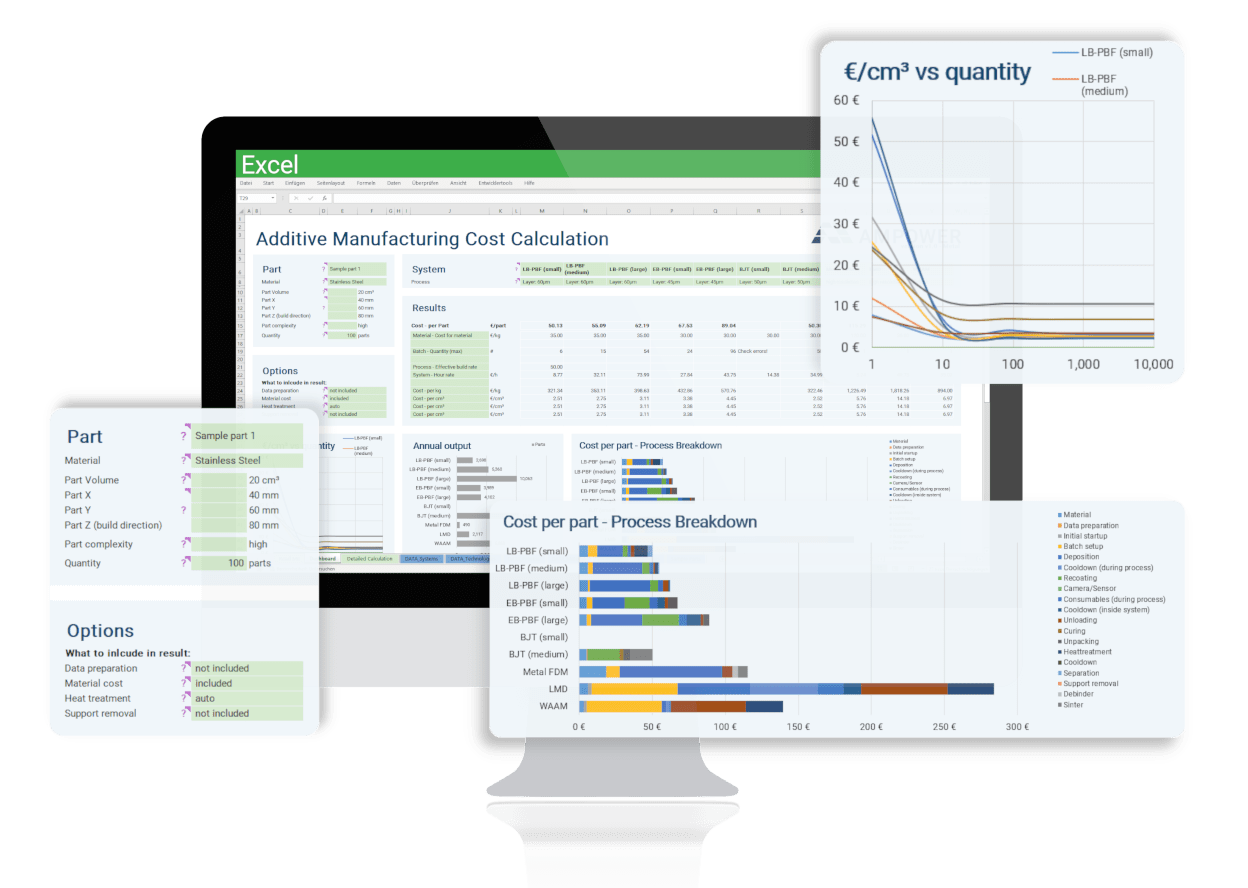

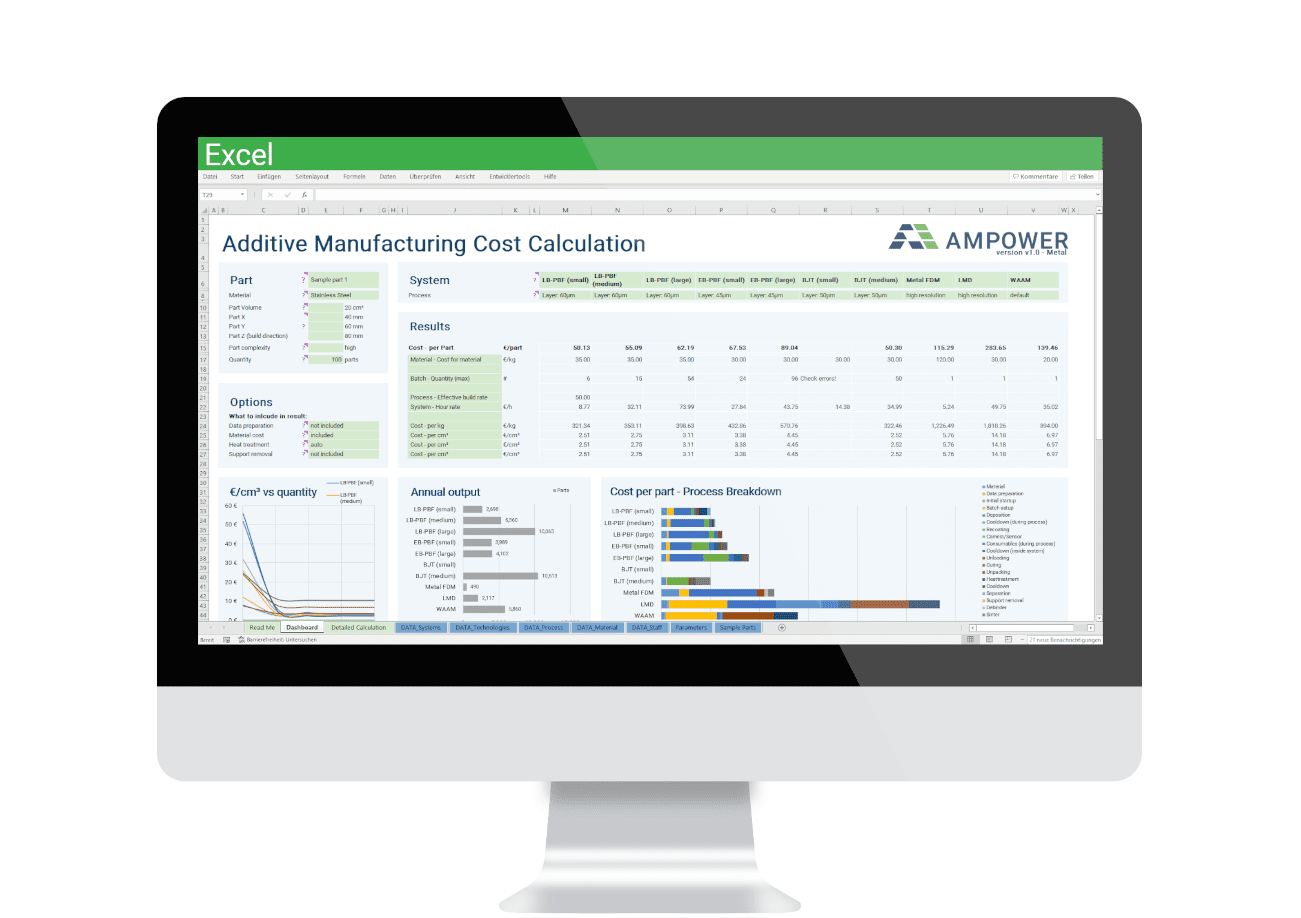

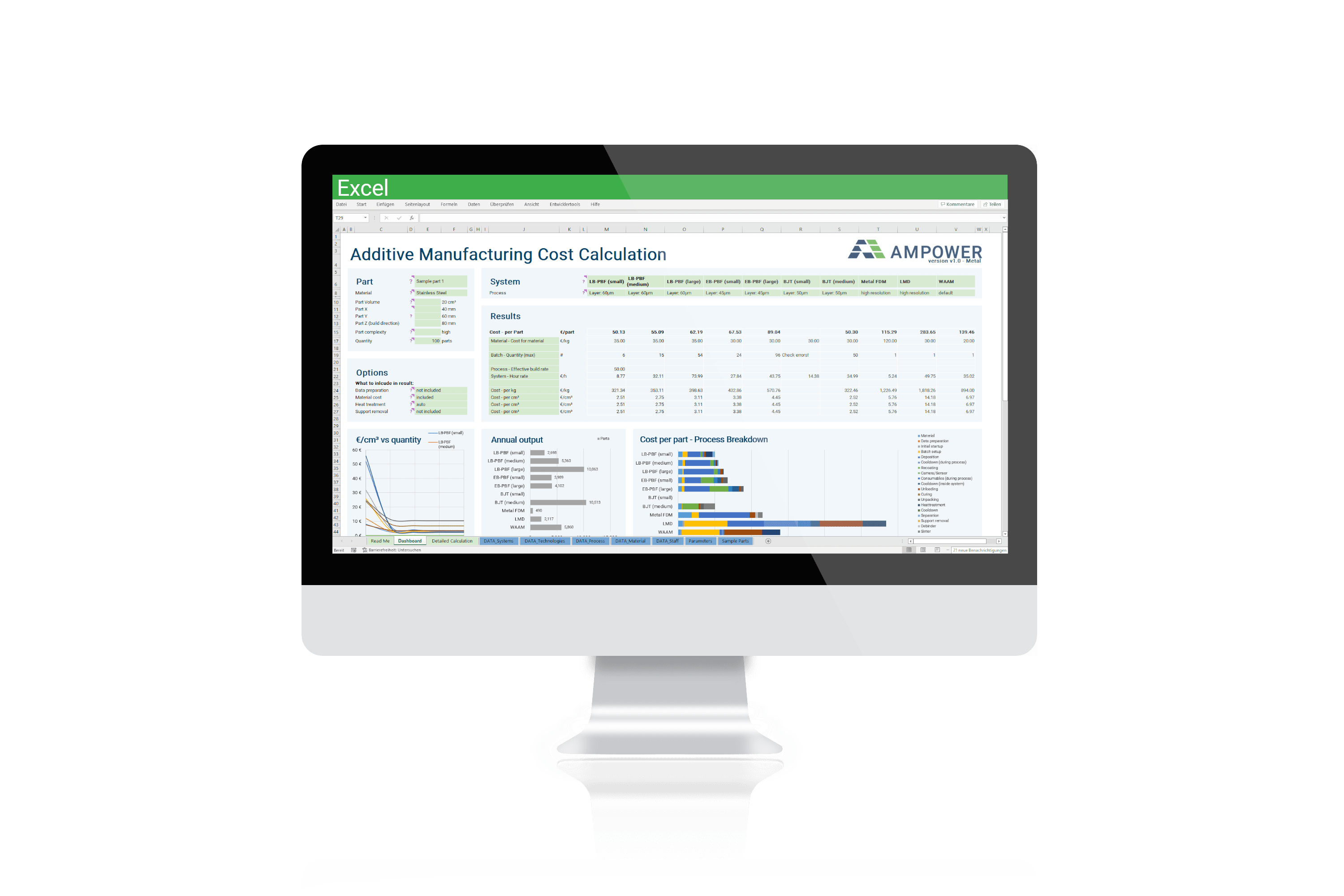

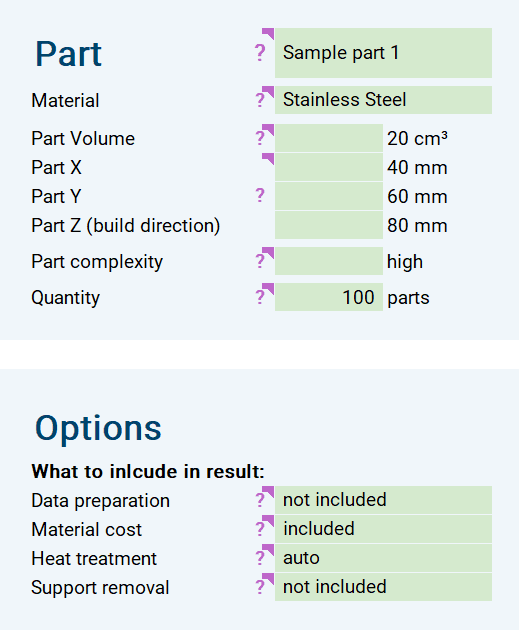

The Additive Manufacturing Cost Calculator is based on a model developed by AMPOWER over the recent years. To feed the model, relevant part data is entered in the dashboard, such as material, dimensions and part volume.

The cost of metal Additive Manufacturing parts is further influenced by the complexity of the part, which is represented by a complexity value. Complex part geometries are, for example, cavities or lattice structures. Process steps that are dependend on the complexity, such as depowdering, will hence have higher cost for higher complexity of a part.

Besides part features, the quantity of parts to be produced is entered. Although Additive Manufacturing is in general beneficial for low quantities, the cost of a single part is significantly dependent on how well the full build volume is utilized.

Additional option fields allow you to further modify the behaviour of the Additive Manufacturing Cost Calculator. Depending on your desired outcome, production steps from the pre and post processing are included or excluded in the assessment.

Fill in the data of the part, you want to calculate.

Chose which pre and post processing steps are included. You can overwrite every value manually.

5 different technologies and platforms can be compared at once.

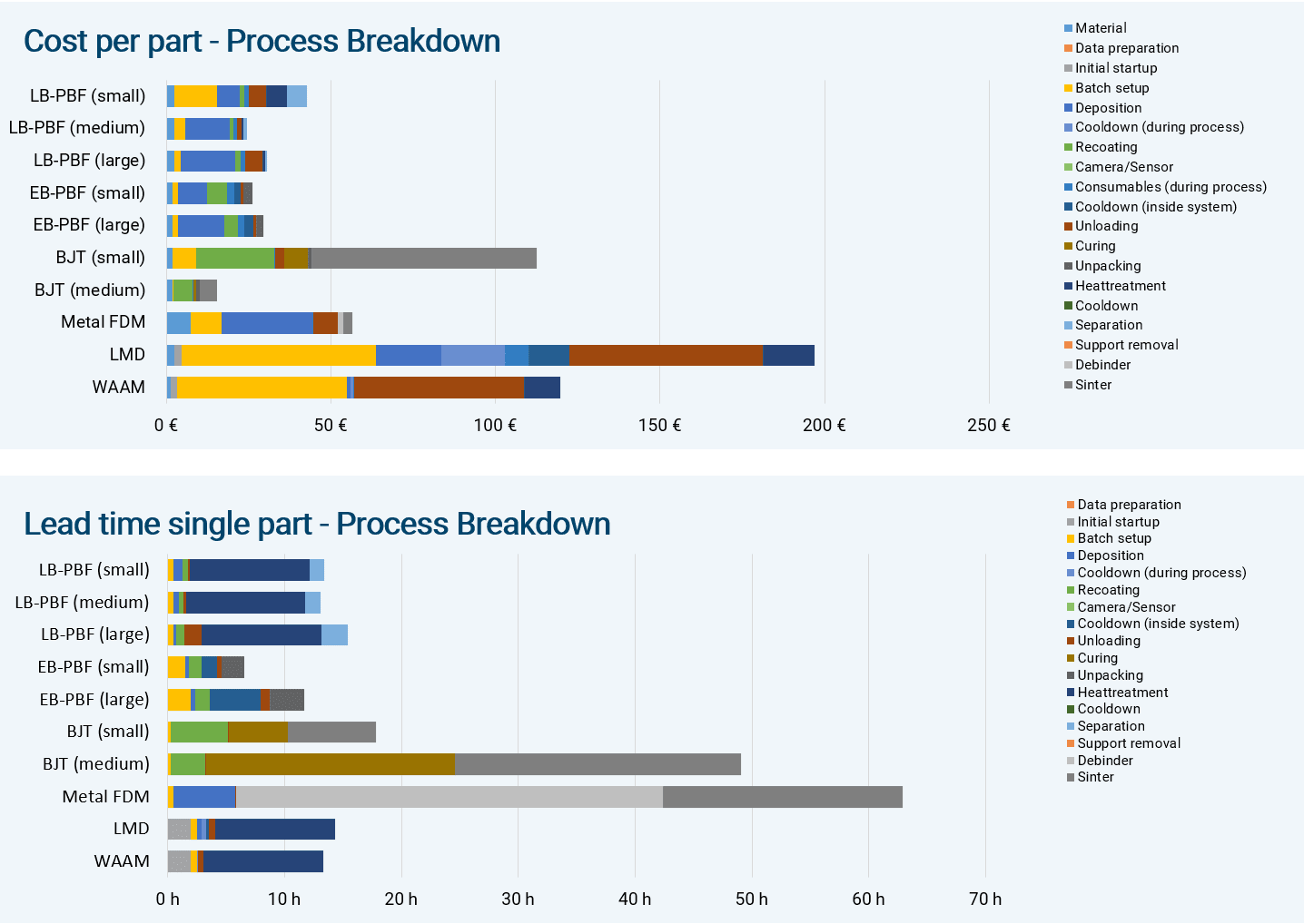

The cost break down includes the complete process chain.

The lead time to produce a single part.

Get the full break down along the process chain

The Additive Manufacturing Cost Calculator provides a full break down of lead time and cost per part on a granular level. Up to 10 different machines and technologies can be compared at a glance.

The Cost Calculator is delivered with generic machines different technologies that are based on real Additive Manufacturing machines. For example the “LB-PBF (large)” machine represents the average performance of large frame metal Powder Bed Fusion machines such as the SLM 500 quad or the EOS M 400-4, to name a few prominent examples.

The cost breakdown includes every process step along the AM process chain and provides valuable insights into each cost segment. Cost drivers can be identified and the performance of different machine classes and technologies can be compared. In many cases post processing can be responsible for the majority of cost for Additive Manfacturing parts.

The AMPOWER Cost Calculator covers the full AM process chain up to the finished raw part. Subsequent processing such as machining, coating, etc. requires external input.

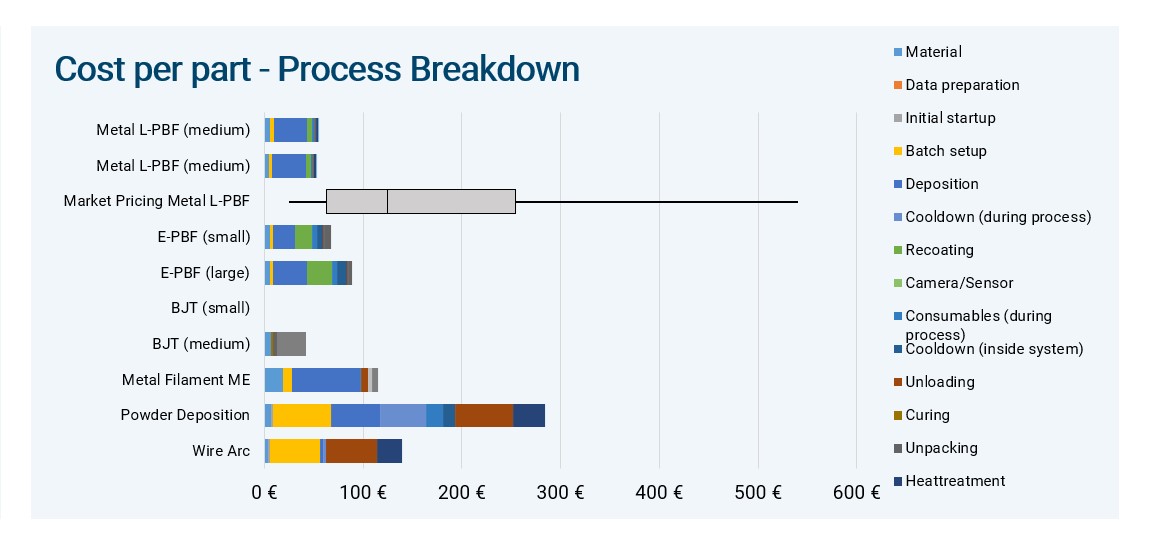

Market pricing at global service bureaus

Based on an assessment of over 5,000 instant quotes from online marketplaces, AMPOWER analyzed the current market pricing, considering technology, material, and production volumes. The data highlights a significant Additive Manufacturing cost reduction up to an order volume of around 100 parts. Moreover, price variations among offers are substantial, ranging between 10-15x for TPU and PA12, and up to 80x for Material Extrusion. ABS parts. In metal Additive Manufacturing, the design strongly affects processability due to thermal stresses, warping, and need of supports. Hence, third party designs are more complex to calculate and the risk for service bureaus of build job failure is much higher without extensive design evaluation or re-design. Surprisingly, many online platforms still offer an instant pricing for L-PBF in multiple materials. This market pricing data can be accessed in the AMPOWER cost calculator.

Average market pricing at global service bureaus

Market pricing range including 50% of market offerings

Market pricing range including nearly all market offerings

The background of the Cost Calculator

Additive Manufacturing cost calculation is mainly driven by three parameters: The first parameter is the material. The Cost Calculator uses the part volume and values for material loss during the process to calculate the material cost. The input here is derived from typical market values based on global market pricing.

The second parameter is the Additive Manufacturing process itself. Significant cost drivers are the machine investment as well as the production time.

The third parameter is the time of the involved manual labor. To calculate Additive Manufacturing part cost, you need to consider the time a technician needs to prepare the machine, unpack a build and remove supports from a part. Optionally the time and cost for digital data preparation is included in the analysis.

Additional cost items are considered as well by the AMPOWER Additive Manufacturing Cost Calculator, such as post processing steps, heat treatment or consumables.

An important differentiator of the AMPOWER Cost Calculator is database derived from real world production build jobs. Based on countless projects and input from machine users, AMPOWER tracks real build duration of all the different metal technologies. This results in validated build speed values and realisitc cost calculations from an independent perspective.

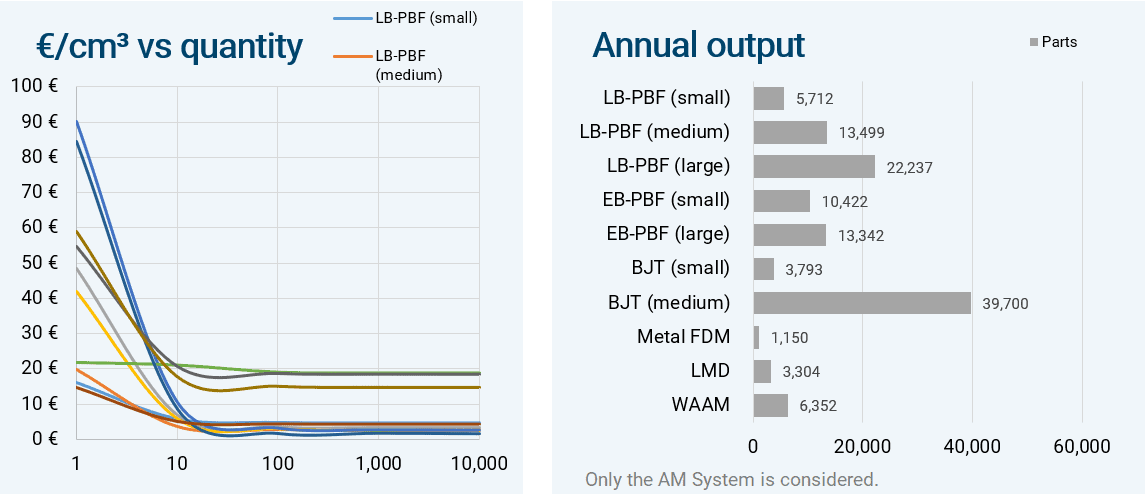

Additive Manufacturing cost depending on quantity

Often, the cost per part is measured in cost per volume (EUR/ccm) or cost per weight (EUR/kg). The manufacturing quantity is one of the main influencing factors for this simplified cost indicator. In the part settings of the calculator, you can define the manufacturing volume. In some cases an increased batch size has the potential to reduce the cost per part. The Additive Manufacturing Cost Calculator analyzes the dependence of cost per volume and manufacturing volume. The resulting graph delineates a calculation based on a quantity range from 1 to 10,000 pieces per year. Usually at around 100-1,000 parts, the Additive Manufacturing cost per volume stays constant and minimum cost is reached. This analysis enables you to arrive rapidly at the lowest, achievable cost per volume for the selected Additive Manufacturing machines.

The Additive Manufacturing cost per volume are typically decreasing until the machine has reached full capacity.

Annual throughput is an importent measurement for production planning.

Regular updates and new releases

Additive Manufacturing technology landscape continuous to be highly dynamic with introduction of new principles paired with rapid advancements and significant progress. AMPOWER tracks all the different technologies and will add them subsequently to the calculator, once validated with independent process data. The AMPOWER technology map currently coveres almost two dozen different working principles for metal Additive Manufacturing. And some new market entries have the potential to become major AM technologies.

Further updates by AMPWOWER will also include new and extended features of the Cost Calculator. Make sure to keep to stay up-to-date with the development on the calculator. Please also make sure to contact us for any features, you would like to see in future versions of the Additive Manufacturing Cost Calculator.