Watch the video tutorial

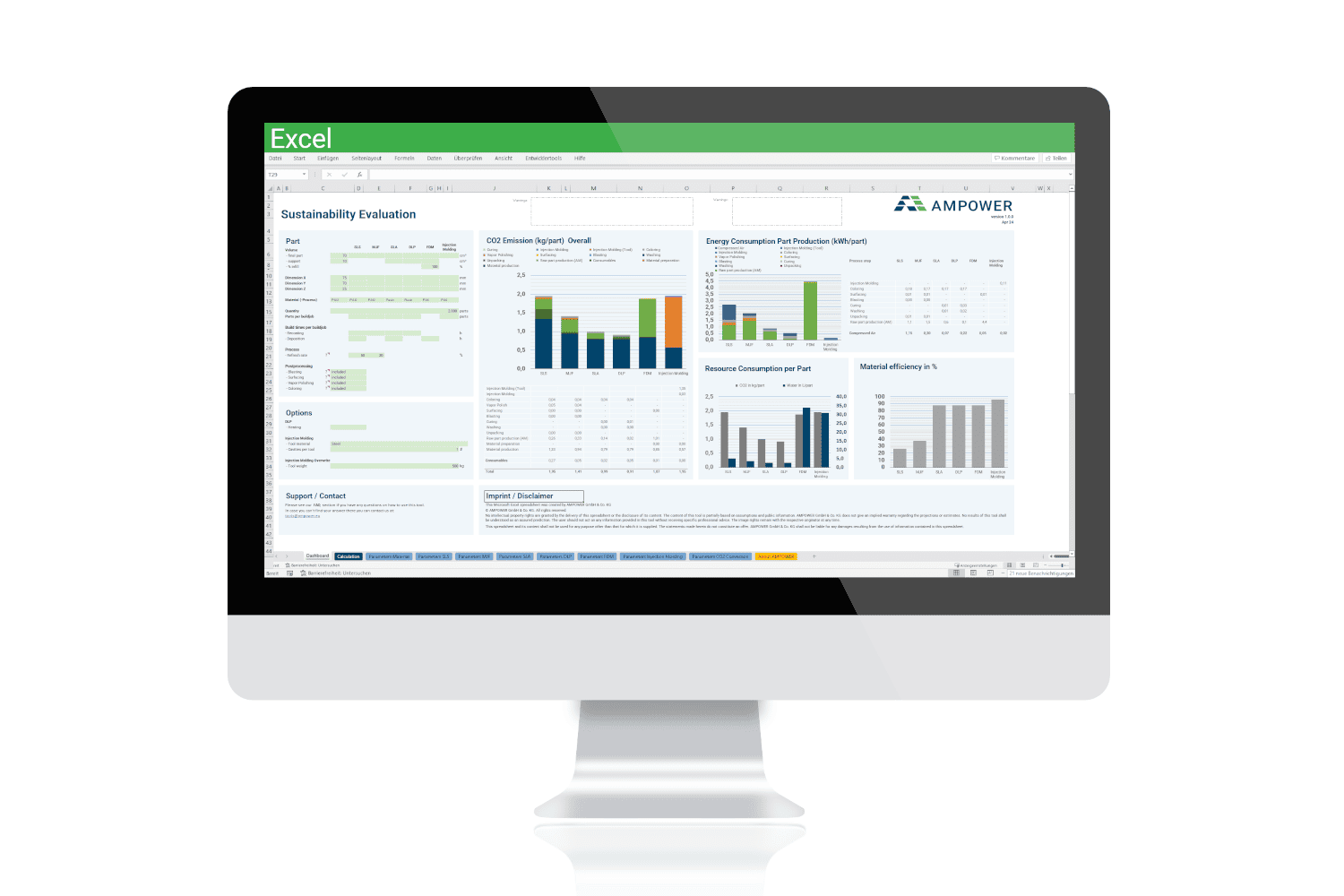

The user interface of the Polymer Calculator is similar to the Metal Calculator

How does the polymer Additive Manufacturing Sustainability Calculator work?

The Additive Manufacturing Sustainability Calculator for polymers encompasses both AM and conventional metal processing technologies. Each manufacturing process is meticulously detailed, breaking down all process steps to a granular level. The description covers mandatory and optional steps, such as powder production, allowing for customization of the process route.

Additionally, the calculator incorporates material recycling at all appropriate stages. The recycling rate can be individually adjusted for feedstock production and for the manufacturing process steps where excess material is produced.

For each process step, a comprehensive model is created, detailing all input and output parameters. Based on this model, the Polymer Additive Manufacturing Sustainability Calculator computes the consumption of energy and consumables and converts these into CO₂ emissions.

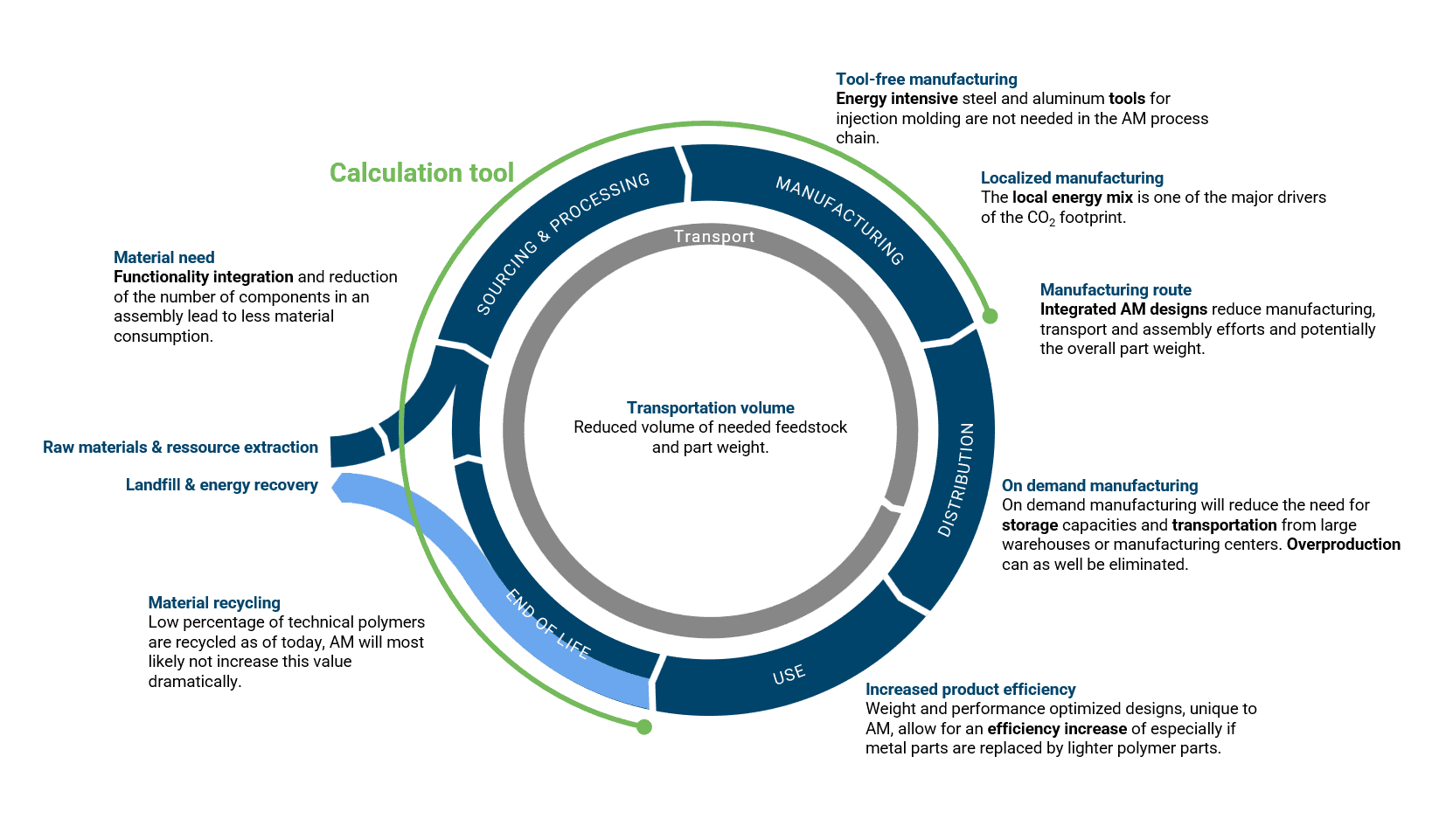

Sustainability Potential for Polymer Additive Manufacturing

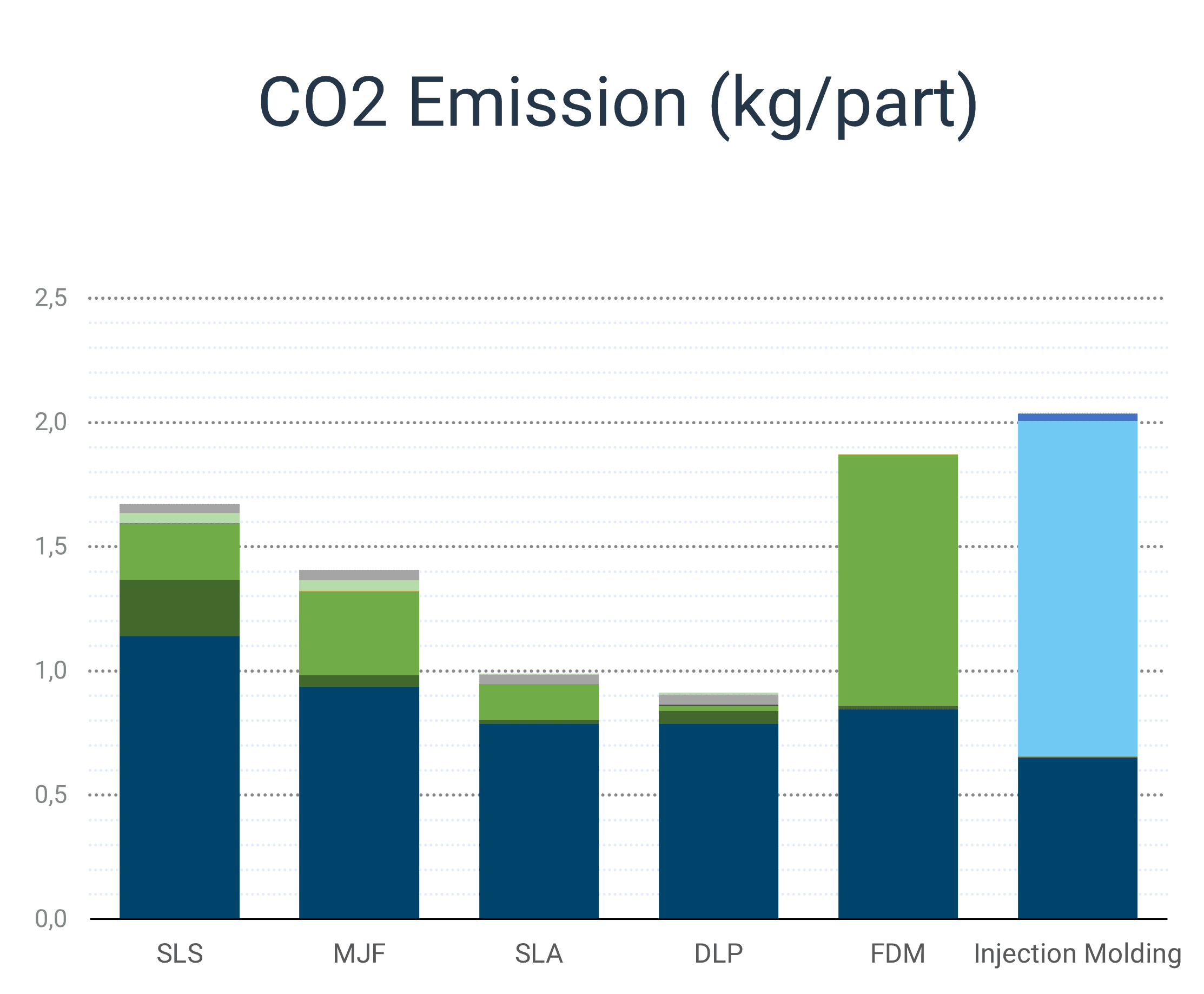

This new calculation tool offers an independent assessment of the CO₂ footprint for polymer Additive Manufacturing parts. Developed by AMPOWER in collaboration with users, material suppliers, and machine manufacturers, the tool not only evaluates CO2 footprint throughout the entire process chain of major polymer Additive Manufacturing technologies but also enables comparisons with Injection Molding.

The sustainability calculator covers AM technologies such as Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Digital Light Processing (DLP), Stereolithography (SLA), and Fused Deposition Modeling (FDM). It supports a wide range of materials, including various polyamides, TPU, polypropylene, PET, PLA, and resins.

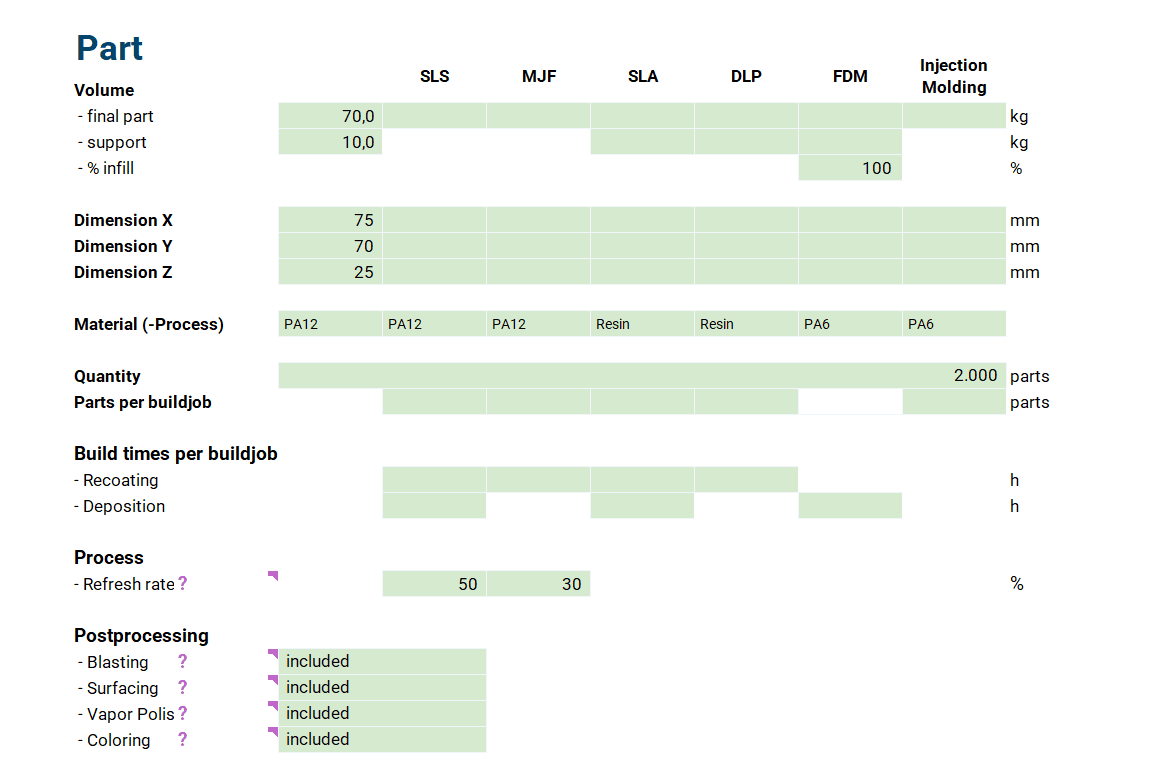

Loading your part into the Additive Manufacturing Sustainability Calculator

The AMPOWER polymer Additive Manufacturing Sustainability Calculator calculates the CO₂ footprint of a part based on its geometry. During the early stages of development and design, many details required for comprehensive Life Cycle Assessments (LCA) are often unknown. However, estimating and comparing the CO₂ footprints of alternative designs and manufacturing technologies becomes a crucial decision-making factor.

AMPOWER’s Sustainability Calculator for polymer provides a fast and easy way to evaluate and compare these footprints. Using a generic approach, the tool requires minimal input parameters to calculate the CO₂ footprint for various manufacturing technologies. Furthermore, if alternative or optimized part designs are developed, the tool allows for direct comparison between conventional and optimized designs. This ensures high result accuracy and a fair comparison across different manufacturing technologies.

Saving energy means saving CO2

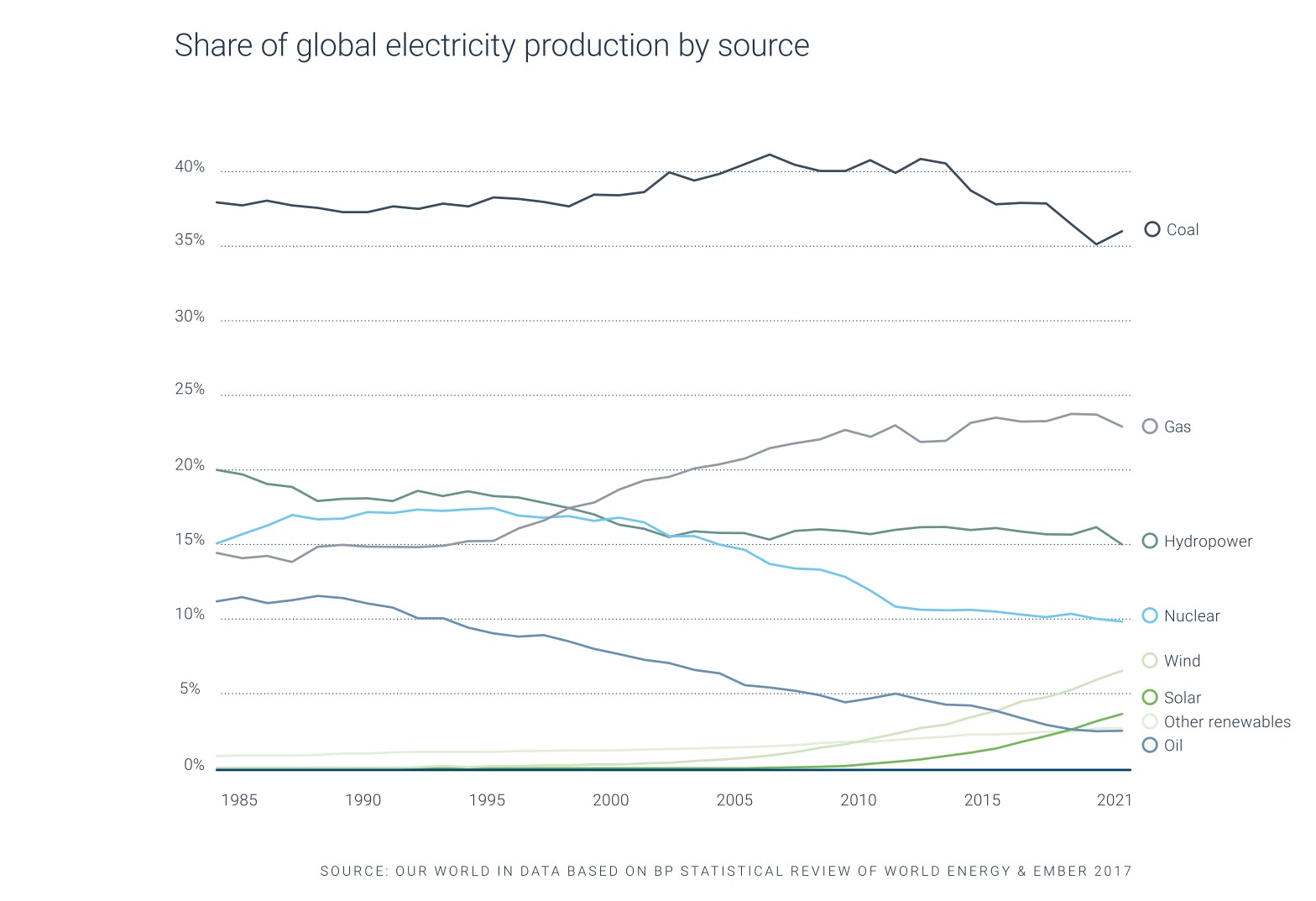

Carbon emissions in manufacturing are directly linked to the energy consumption throughout the process chain. Therefore, CO₂ emissions can be most effectively reduced by sourcing renewable energy or by decreasing overall energy consumption.

Manufacturing companies can potentially reduce or even eliminate their carbon footprint by sourcing renewable energy. However, calculations indicate that the global increase in energy consumption makes it nearly impossible to rely solely on renewable energy. Achieving carbon emission goals requires not only a shift to renewable energy but also a significant reduction in overall energy consumption.

This is why the polymer Additive Manufacturing Sustainability Calculator primarily focuses on the energy consumption of each process step. By understanding and optimizing the energy use at every stage, companies can better manage and reduce their carbon footprint, making the manufacturing process more sustainable.