Branch Manager Aerospace, TRUMPF Laser-und Systemtechnik GmbH

Customers from regulated or high performance industries that purchase your Additive Manufacturing machines have to meet certain requirements. AMPOWER advises you as a supplier how to best support your customer. We help you to understand the industry’s requirements and what the customers needs to qualify your system to produce a validated product. The goal is to enable your customer to achieve a fast production ramp-up with your product.

System suppliers deliver machines to numerous industries that each have their own set of specific demands. The customers, especially from regulated industries, expect the machines and their documentation to meet the existing requirements. AMPOWER supports machine suppliers by providing everything necessary, so your customer can quickly qualify their machines and begin with the production ramp-up. Our service includes an assessment of your machine technology, evaluation of the documentation you provide as well as analysis of your procedures in service and maintenance. We challenge you so you can deliver the best customer experience!

Assessment of your machine and your documentation to customer requirements and expectations in order to quickly ramp-up production

Support to develop qualification procedures and documents that you can deliver to your customers

Directly support your customer with our expertise and best practice in qualification

The initial Gap Analysis has the goal to find deviations of your value proposition with industry specific requirements in mind. The analysis includes your AM machine, but periphery solutions as well as the documentation and service procedures. Additionally, we will provide a training of your personnel with best practices in machine qualification and give an overview on the current regulatory framework in the largest AM industries. The results from the Gap Analysis is a prioritized list of shortcomings, potential improvements and opportunities for competitive advantages.

Once a customer begins their journey with you, they expect you as system supplier to take away their work when it comes to qualification of the machine. AMPOWER can provide you with guidance on best practices of machine qualification and prepare a full set of templates that meets the expectation of your customer’s quality management. This enables your customer to quickly overcome this milestone and begin production.

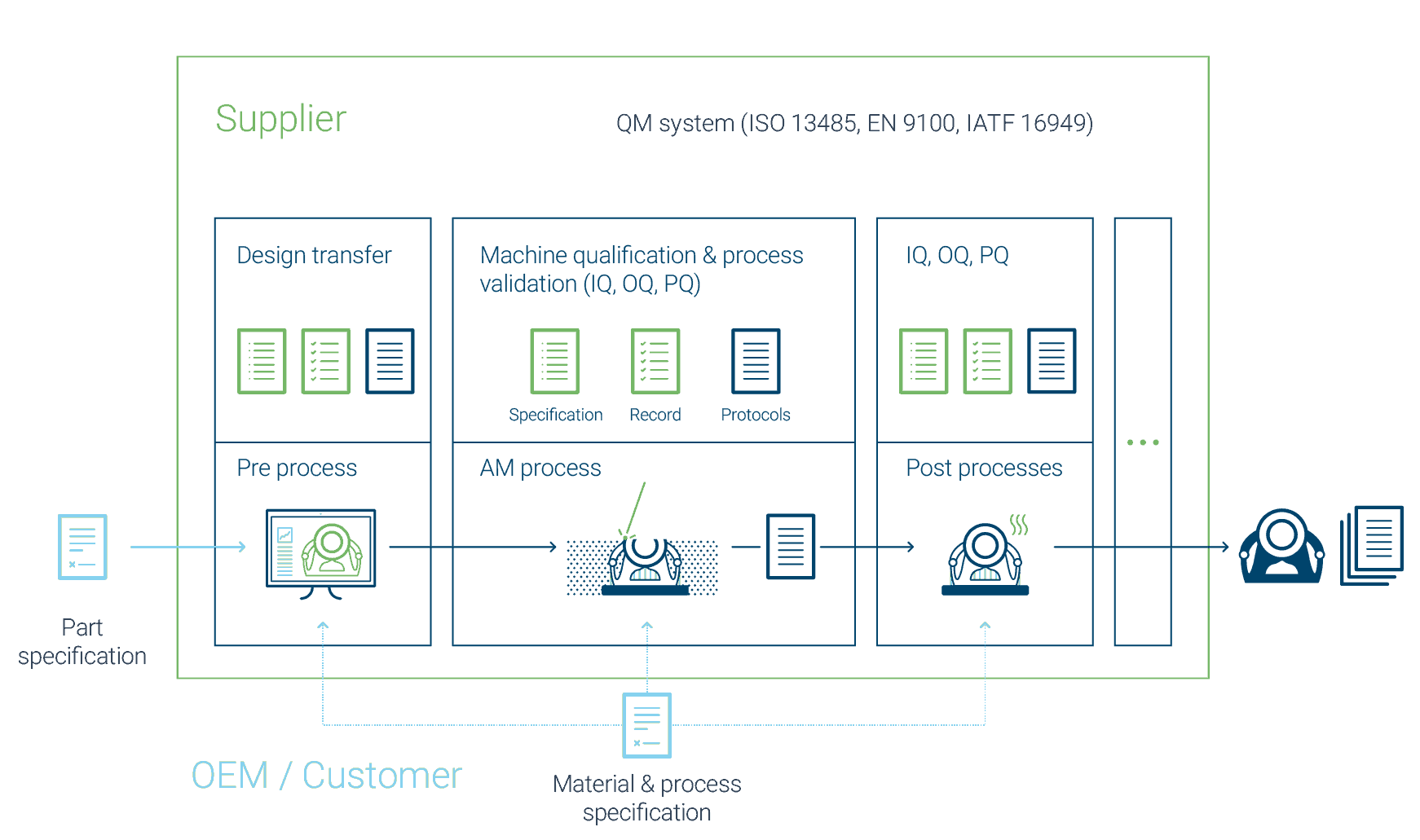

The part specification defines all the properties of the component. The user specifies these, for example in the form of a technical drawing.

The material specification determines the properties of the starting material and partly also of the input material. These can be strength values as well as chemical composition and density. The Process specification defines the parameters and requirements of the manufacturing process.

Each delivered component or batch contains a documentation that proves that the components meet the specifications.

We support you and your customer to successfully use Additive Manufacturing technology in a regulated environment. Introduction of AM in a regulated framework requires a holistic approach that includes the production department, but also R&D, purchasing and general management. AMPOWER provides the needed expertise and supports with the implementation of proved cross-industry best practices. Our support ranges from weekly calls to on-site support to achieve machine qualification and production ramp-up as quickly as possible. This includes necessary documents in form of risk assessment, development of specification and qualification packages as well as deviation and mitigation management.

General quality management in medical technology is defined by ISO 13485. The specifications for the quality management of Additive Manufacturing are based on the component specifications and international guidelines such as those of the U.S. FDA.

The EN/AS 9100 provides the framework for quality management in aviation. In addition, the OEM specifies requirements for the qualification Additive Manufacturing.

The IATF 16949 defines the general framework of quality management in the automotive industry. To date, only few specifications have been published for Additive Manufacturing.